Abbotsford Homeowner's Guide to Choosing Glass Railings

Dec 14, 2025

Abbotsford's position as the Hub of the Fraser Valley makes it the natural center for glass railing services across the region. Officially recognized by the Abbotsford Chamber of Commerce (2016) as the valley's economic and geographic hub, this growing city of over 153,000 residents connects communities from Vancouver to Hope along the corridor.

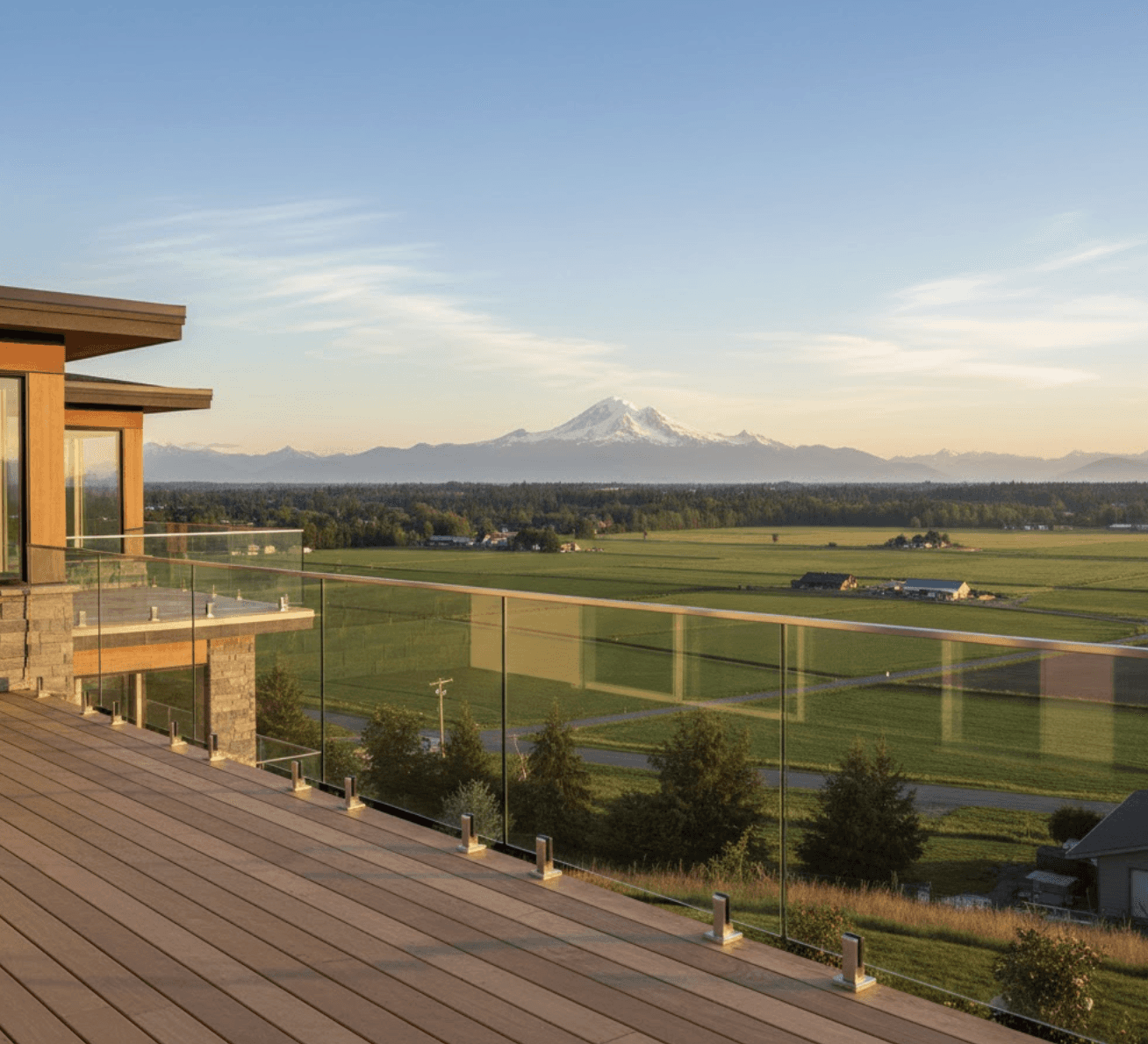

Glass railings have become the top choice for Abbotsford homeowners who want to preserve their mountain and valley views while meeting BC Building Code requirements. Whether you overlook Mount Baker, agricultural land, or the Fraser River, modern glass systems offer unobstructed sightlines that traditional wood or metal railings cannot match.

This guide explains everything Abbotsford homeowners need to know about choosing, installing, and maintaining glass railings in the Fraser Valley's unique climate. You will learn about available systems, BC Building Code requirements, climate considerations, and what to expect during the installation process.

Why Abbotsford Homeowners Choose Glass Railings

Abbotsford's blend of urban convenience and natural beauty creates the perfect environment for glass railing systems. Three main factors drive the decision to upgrade from traditional railings.

Unobstructed Views of Mount Baker and Fraser Valley

Abbotsford's unique geographic position offers stunning views across the Fraser Valley agricultural lands, with Mount Baker visible to the south on clear days. Glass railings preserve these sightlines in ways that wood pickets or metal balusters simply cannot.

Traditional railing systems create visual barriers. Wood posts every few feet interrupt your view. Metal balusters create a "cage" effect that diminishes outdoor spaces. Frameless glass railings eliminate these obstructions completely.

The benefit extends beyond aesthetics. Properties with preserved views command higher resale values in Abbotsford's growing market. Modern glass systems signal quality upgrades that appeal to the wave of new residents moving to the Fraser Valley each year.

Key view benefits include:

Complete transparency - no visual interruption from your deck or balcony

Light transmission - glass allows natural light to reach lower levels and indoor spaces

Modern aesthetic - clean lines match contemporary Fraser Valley architecture

Property differentiation - glass railings make homes stand out in competitive markets

Low Maintenance in Fraser Valley's Wet Climate

The Fraser Valley receives close to 1,600 millimetres of precipitation annually, with 75% falling between October and April (BC Climate Change Adaptation Program, 2023). This extended wet season creates challenging conditions for traditional railing materials.

Wood railings absorb moisture during these months. The constant wet-dry cycles cause warping, cracking, and rot. Even pressure-treated lumber requires annual staining and sealing to prevent deterioration. Within 5-7 years, most wood railings show significant wear.

Metal railings face similar challenges. Standard aluminum oxidizes. Steel rusts. Painted finishes chip and peel, requiring regular maintenance to prevent corrosion from spreading.

Glass performs differently. The material itself is unaffected by moisture. Rain simply runs off the surface. No absorption means no warping, no rot, and no structural degradation over time.

Maintenance requirements are minimal:

Monthly rinse with fresh water during wet months (10-15 minutes)

Quarterly cleaning with mild soap solution (30 minutes)

Annual inspection of mounting hardware (15-20 minutes)

No painting or staining ever required

Compare this to wood railings that demand annual staining (6-8 hours), regular sanding, and eventual replacement. The time savings compound over decades of ownership. For detailed maintenance guidance, see our coastal BC cleaning guide.

Property Value Enhancement in Abbotsford's Growing Market

Abbotsford's population has grown to 153,524 residents as of 2024, representing 3.3% annual growth (Statistics Canada, 2024). This expansion brings new homeowners who expect modern amenities and quality construction.

The median household income in Abbotsford is $90,000 annually (Statistics Canada, 2021). This income level supports home improvement investments that enhance property value and livability.

Glass railings signal quality to prospective buyers. The upgrade demonstrates attention to detail and willingness to invest in premium materials. When homes enter the resale market, glass railing systems differentiate properties from competing listings.

Market advantages include:

Modern appeal - attracts buyers seeking contemporary design

Perceived value - glass systems are recognized as premium upgrades

Durability assurance - demonstrates quality construction standards

Move-in ready - eliminates immediate railing replacement concerns for buyers

Glass Railing Systems Available in Abbotsford

Three main glass railing systems serve Abbotsford properties, each suited to different architectural styles, budgets, and performance requirements. Understanding the distinctions helps homeowners make informed decisions.

Frameless Glass Railings

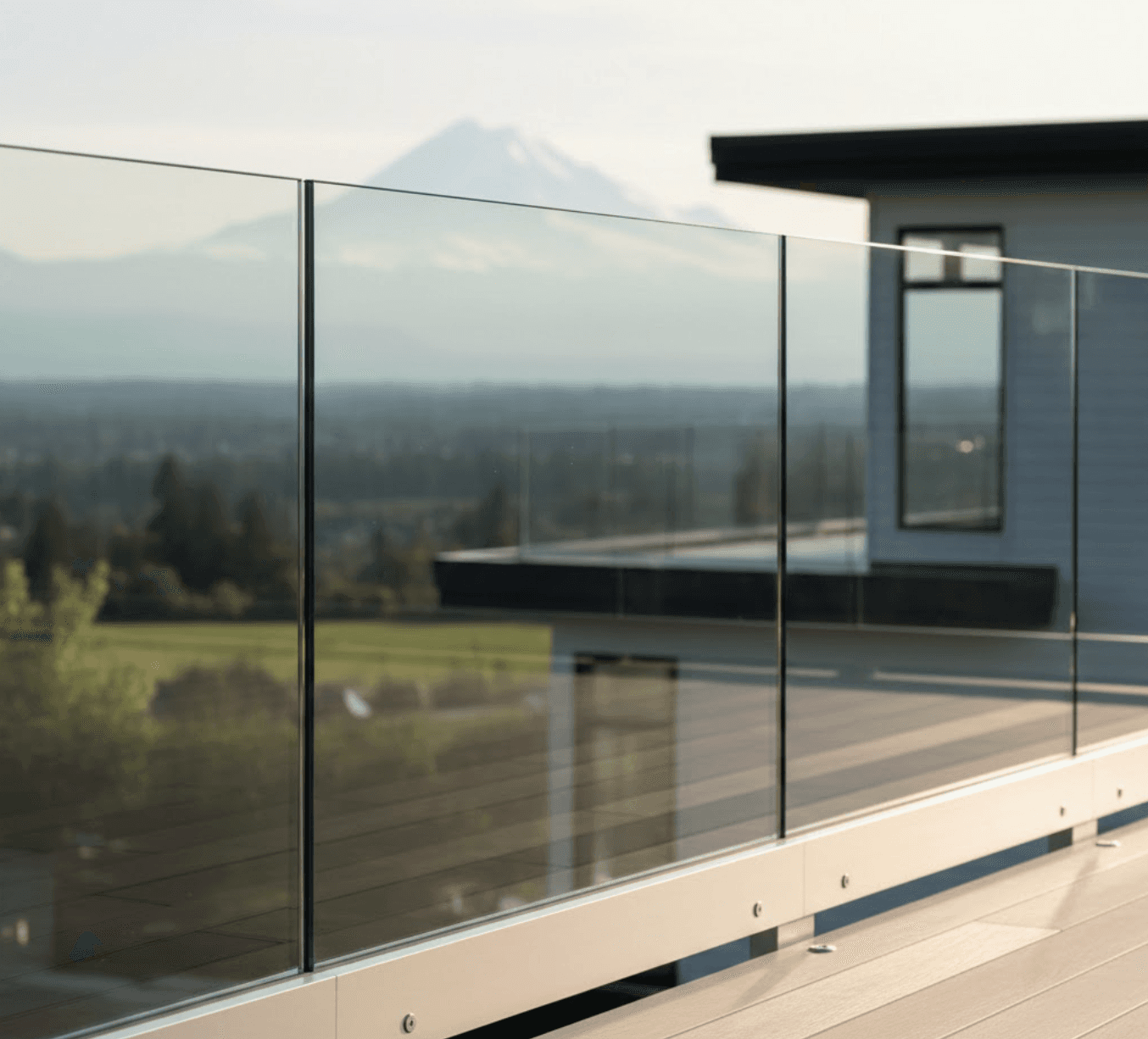

Frameless systems represent the pinnacle of modern minimalism. Glass panels mount using specialized hardware with no visible top or bottom rails obstructing views. The result is maximum transparency and clean architectural lines.

This system type requires precise engineering. The BC Building Code 2024 mandates engineer-sealed shop drawings for frameless installations. These drawings verify load capacity and glass specifications meet safety standards.

Frameless characteristics include:

No top rail - glass panels stand alone without horizontal supports

Specialized mounting - base channels, standoffs, or spigot systems

Maximum views - absolute minimum visual obstruction

Engineering required - certified calculations for structural compliance

Premium positioning - highest cost category among glass systems

Best applications for frameless railings:

View properties overlooking Fraser Valley or mountains

Modern architectural designs

Properties where sightlines are the primary consideration

Homeowners prioritizing aesthetics over budget constraints

Semi-Frameless Glass Railings

Semi-frameless systems balance modern aesthetics with practical considerations. Aluminum posts support glass panels at regular intervals (maximum 42 inches apart per BC Building Code). A top rail connects the posts, creating a complete safety barrier.

This configuration simplifies BC Building Code compliance. The top rail provides load distribution that makes engineering calculations more straightforward. Installation becomes faster and more cost-effective.

Semi-frameless characteristics include:

Aluminum posts - powder-coated for weather resistance

Glass panels - fitted between posts for clarity

Top rail included - meets code requirements easily

Standard engineering - less complex than frameless systems

Cost-effective - lower price point than frameless

Best applications for semi-frameless railings:

Budget-conscious projects maintaining quality

Traditional home styles where subtle framing is acceptable

Properties where slight visual interruption is not a concern

Homeowners seeking easier permitting and installation

Curved Glass Railings

Curved glass systems follow architectural curves rather than straight lines. Custom fabrication creates panels that match exact radius measurements. The result is flowing design that complements curved staircases, rounded balconies, and unique architectural features.

This customization requires specialized engineering and fabrication. Each curved panel is manufactured specifically for your project. Lead times extend beyond standard systems due to this custom work.

Curved characteristics include:

Custom radius - fabricated to your exact measurements

Flowing lines - follows architectural curves seamlessly

Unique installations - no two projects identical

Extended timeline - 8-10 weeks typical for fabrication

Premium investment - custom engineering and manufacturing

Best applications for curved railings:

Spiral or curved staircases

Rounded balconies and decks

Properties with unique architectural elements

Homeowners seeking distinctive design features

System Comparison

Feature | Frameless | Semi-Frameless | Curved |

|---|---|---|---|

View Obstruction | Minimal | Slight (posts visible) | Minimal |

Installation Time | 6-8 weeks | 6-8 weeks | 8-10 weeks |

BC Code Compliance | Engineer required | Standard compliance | Engineer required |

Best For | Modern homes | Budget projects | Unique designs |

Maintenance | Low | Low | Low |

For detailed system comparison, review our frameless vs semi-frameless guide.

BC Building Code Requirements for Abbotsford Glass Railings

The BC Building Code 2024 came into effect March 8, 2024 (Province of British Columbia, 2024). All glass railing installations in Abbotsford must comply with current code requirements. Understanding these standards helps homeowners plan projects correctly from the start.

When Guards Are Required

Guards become mandatory when vertical drops exceed specific thresholds. The BC Building Code 2024, Division B, Section 9.8 establishes these requirements clearly.

Any platform with a drop of more than 600mm (24 inches) requires guard railings on sides without wall protection (BC Building Code 2024, 2024). This applies to:

Decks and patios

Balconies

Raised walkways

Stairway landings

Mezzanines

Even decks below the 600mm threshold often benefit from glass railings. The aesthetic upgrade and defined space make lower installations worthwhile for many Abbotsford homeowners.

Minimum Guard Heights

Guard height requirements vary based on platform elevation above grade. The BC Building Code 2024 Division B, Section 9.8 specifies exact minimums.

For decks up to 1.8 metres (5 feet 10 inches) above grade, guards must reach a minimum height of 900mm (36 inches) measured vertically from the deck surface. For decks or balconies above 1.8 metres, the minimum height increases to 1,070mm (42 inches) (BC Building Code 2024, 2024).

These measurements are minimums. Many homeowners choose taller guards for enhanced safety or design preferences. Abbotsford building inspectors verify height compliance during final inspection.

Critical height considerations:

Measurement point - from walking surface to top of guard

Consistent height - must maintain minimum along entire length

No gaps - continuous protection without breaks

Inspector verification - measured during building inspection

Glass Safety Standards

Glass used in guard applications must meet specific safety performance standards. The BC Building Code 2024, Section 9.6 Glass and Glazing references national standards for material specifications.

All glass must conform to CAN/CGSB-12.1-M90, the Canadian General Standards Board standard for Tempered or Laminated Safety Glass published November 1990 (Government of Canada, 2016). This federal standard ensures glass breaks safely or remains intact after impact.

Alternative compliance includes CAN/CGSB-12.20-M89 for Structural Design of Glass for Buildings. This standard addresses load-bearing calculations and engineering requirements.

Frameless glass railing systems require additional documentation. Engineer-sealed shop drawings must verify load capacity and glass specifications. These calculations demonstrate compliance with lateral load requirements and safety factors.

Safety standard requirements:

Tempered or laminated - must meet CAN/CGSB-12.1-M90

Impact resistance - tested to withstand human impact loads

Load capacity - verified through structural calculations

Professional engineering - sealed drawings for frameless systems

For comprehensive code compliance details, see our BC Building Code requirements guide.

Glass Railing Costs in Abbotsford

Cost represents the primary concern for most Abbotsford homeowners considering glass railings. Multiple factors influence final project pricing, making every installation unique.

What Affects Glass Railing Costs

Glass railing projects vary significantly based on specific site conditions and homeowner preferences. No two Abbotsford properties present identical requirements.

System type creates the largest cost variation. Frameless systems require engineer-sealed drawings and specialized mounting hardware. Semi-frameless installations use standard aluminum components. Curved glass demands custom fabrication for each panel.

Linear footage directly impacts total cost. A 20-foot deck requires less material and labor than a 60-foot wraparound balcony. Complex layouts with corners, stairs, and multiple levels increase installation time and material waste.

Site accessibility affects labor efficiency. Urban Abbotsford properties with easy driveway access differ from rural locations requiring longer material transport. Second-story installations require additional safety equipment and time.

Hardware finish selection influences material costs. Standard powder-coated aluminum serves most applications. Marine-grade 316 stainless steel provides superior corrosion resistance in coastal-influenced areas but carries premium pricing.

Engineering requirements add to frameless system costs. Structural calculations, sealed drawings, and permitting create upfront expenses that semi-frameless systems avoid.

Key cost factors include:

System type - frameless vs semi-frameless vs curved

Total linear footage - materials and labor scale with distance

Deck complexity - corners, stairs, and levels add time

Site accessibility - urban vs rural property access

Hardware finish - standard vs marine-grade stainless steel

Engineering needs - sealed drawings for frameless systems

Why Costs Vary Between Projects

Every Abbotsford property presents unique conditions. Deck height, structural mounting points, access constraints, and homeowner preferences all influence final pricing.

Custom measurements ensure perfect fit. Glass panels are cut to exact dimensions for your specific installation. This precision eliminates the guesswork and ensures proper code compliance.

Quality materials and professional installation represent investments in long-term performance. Glass railing systems properly designed for Fraser Valley conditions last decades with minimal maintenance. The upfront cost reflects engineering, materials, and craftsmanship that deliver reliable results.

Timeline considerations matter. Standard installations require 6-8 weeks from initial measurement to final completion. This includes engineering review (1-2 weeks), fabrication (2-3 weeks), permitting if required (1-2 weeks), and installation (1-2 weeks).

The best approach is scheduling a free on-site consultation. This allows accurate assessment of your specific property, discussion of system preferences, and development of a detailed quote. Learn more about our Abbotsford services.

Fraser Valley Climate Considerations for Glass Railings

The Fraser Valley's unique microclimate creates specific requirements for outdoor building materials. Understanding these conditions helps homeowners select systems designed for long-term performance.

High Rainfall and Drainage Requirements

The Fraser Valley receives average annual precipitation of close to 1,600 millimetres, with 75% falling between October and April (BC Climate Change Adaptation Program, 2023). This extended wet season lasts six months, exposing exterior materials to constant moisture.

Proper drainage design prevents water pooling at railing bases. Quality installations slope mounting channels to direct water away from posts and fasteners. Weep holes allow any trapped moisture to escape rather than accumulating inside mounting systems.

Glass panels themselves shed water naturally. Rain runs off the smooth surface without absorption. This characteristic prevents the rot and deterioration that plague wood railings in wet climates.

Hardware selection matters in high-precipitation environments. Stainless steel fasteners resist corrosion better than standard aluminum. Powder-coated finishes protect against moisture infiltration. Proper sealants prevent water from entering mounting points where it could compromise structural integrity.

Rainfall considerations include:

Base drainage - mounting systems must allow water escape

Hardware protection - stainless steel resists corrosion

Sealant quality - prevents moisture infiltration at mounting points

Installation precision - proper slopes and weep holes prevent pooling

Temperature Fluctuations and Freeze-Thaw Cycles

The Fraser Valley enjoys one of Canada's longest frost-free periods (BC Climate Change Adaptation Program, 2023). However, freeze-thaw cycles still occur between November and March.

These cycles create expansion and contraction in building materials. Water enters small cracks or gaps, freezes overnight, and expands. Daytime thawing allows more water entry. The cycle repeats dozens of times each winter.

Inferior materials fail under this stress. Standard fasteners work loose. Poor-quality sealants crack and separate. Mounting points shift, compromising structural integrity.

Marine-grade 316 stainless steel hardware resists these forces. The material's composition prevents expansion-driven failure. Quality sealants maintain flexibility through temperature changes, staying bonded to glass and mounting surfaces.

Glass itself remains unaffected by temperature fluctuations. The material neither expands significantly nor contracts. This stability makes glass ideal for climates with variable winter conditions.

Temperature considerations include:

Hardware quality - marine-grade stainless resists expansion stress

Sealant flexibility - maintains bonds through freeze-thaw cycles

Mounting stability - proper installation prevents shifting

Glass durability - unaffected by temperature changes

Coastal Influence and Salt Air

Abbotsford sits approximately 45 minutes from the Pacific coast. While not directly oceanfront, the Fraser Valley experiences coastal influence through prevailing winds that carry salt air inland.

Salt accelerates corrosion in metal components. Standard aluminum oxidizes faster in salt-affected environments. Hardware finishes degrade more quickly. The cumulative effect shortens component lifespan significantly.

Monthly fresh water rinses remove salt deposits before they cause damage. This simple maintenance step extends hardware life by years. The process takes 10-15 minutes and requires only a garden hose.

Marine-grade 316 stainless steel hardware provides superior salt resistance compared to standard 304 stainless or aluminum. The enhanced corrosion protection justifies the modest cost premium in coastal-influenced areas.

Glass panels remain unaffected by salt exposure. The smooth surface prevents salt adhesion. Rinses remove any deposits without special cleaning products or abrasive scrubbing.

Coastal influence considerations:

Salt air transport - inland areas still experience corrosion effects

Hardware selection - marine-grade 316 stainless steel recommended

Monthly rinsing - removes salt before corrosion begins

Glass resistance - material unaffected by salt exposure

For detailed climate-specific maintenance, review our coastal BC maintenance guide.

The Glass Railing Installation Process in Abbotsford

Understanding the installation process helps Abbotsford homeowners set realistic expectations and prepare their properties appropriately. The process follows four distinct phases over 6-8 weeks.

Step 1: On-Site Measurement

Every project begins with on-site consultation at your Abbotsford property. Initial assessment covers deck layout, mounting points, access considerations, and homeowner preferences.

Precise laser measurements capture exact dimensions. These measurements account for every corner, stair, and level change. Accuracy at this stage ensures perfect panel fit during installation.

Site assessment identifies mounting points and structural considerations. Quality installations anchor to structural framing rather than surface decking. This distinction ensures long-term stability and code compliance.

Discussion covers system preferences and budget parameters. Homeowners review frameless, semi-frameless, and curved options. Material selections address hardware finishes and glass specifications.

Measurement phase includes:

Property visit - consultation at your Abbotsford location

Laser measurement - precise dimension capture

Structural assessment - mounting point identification

System discussion - preferences and budget alignment

Timeline planning - project schedule development

Step 2: Engineering and Fabrication (Weeks 1-4)

Engineering review begins immediately after measurement. For frameless systems, structural engineers prepare sealed shop drawings. These calculations verify load capacity and glass specifications meet BC Building Code requirements.

Building permit applications proceed if required by Abbotsford building department. Most glass railing installations on decks over 600mm above grade require permits. The application includes engineered drawings, material specifications, and installation plans.

Glass panels are cut to exact specifications during fabrication. Custom dimensions ensure perfect fit without field modifications. Quality control checks verify measurements match engineering drawings.

Hardware components are ordered or fabricated based on system specifications. Mounting brackets, posts, top rails, and fasteners arrive ready for installation. Marine-grade stainless steel components undergo additional quality verification.

Engineering and fabrication includes:

Structural calculations - engineer-sealed shop drawings

Permit applications - submitted to Abbotsford building department

Glass fabrication - panels cut to exact dimensions

Hardware preparation - components ordered and verified

Quality control - measurements confirmed against specifications

Step 3: Professional Installation (Weeks 5-6)

Installation begins with hardware mounting to structural framing. Proper anchoring ensures long-term stability and code compliance. Surface decking cannot support guard loads and creates inspection failures.

Glass panels are precisely positioned into mounting systems. Careful handling prevents chips or cracks during installation. Panel alignment ensures even spacing and proper drainage.

All connections undergo weather-tightness verification. Sealants protect mounting points from water infiltration. Hardware tightness prevents shifting under load.

Final inspection walkthrough confirms every detail meets standards. Homeowners review the completed installation, ask questions, and receive maintenance guidance specific to Fraser Valley climate.

Professional installation includes:

Structural mounting - hardware anchored to framing

Panel positioning - glass installed with precision

Weather sealing - connections protected from moisture

Quality verification - every connection checked

Homeowner walkthrough - final review and guidance

Step 4: Final Inspection and Handover (Weeks 6-8)

Municipal building inspection verifies code compliance. Abbotsford inspectors check guard height, spacing, and structural mounting. Systems designed properly pass inspection on the first visit.

Complete documentation is provided for building inspector review. This includes engineer-sealed drawings for frameless systems, material certifications, and installation verification.

Maintenance guidance specific to Fraser Valley climate helps homeowners protect their investment. Monthly rinsing schedules, quarterly cleaning procedures, and annual inspection checklists ensure long-term performance.

Warranty information covers materials and workmanship. Quality installations backed by proper warranties provide peace of mind for decades.

Final inspection and handover includes:

Municipal inspection - Abbotsford building department review

Documentation provision - engineered drawings and certifications

Maintenance guidance - Fraser Valley-specific care instructions

Warranty information - material and workmanship coverage

For detailed installation insights, see our professional installation guide.

Maintaining Glass Railings in Abbotsford's Climate

Low maintenance does not mean no maintenance. Simple routine care preserves glass railing clarity and structural integrity for decades in Fraser Valley conditions.

Monthly Rinse Schedule (October-April)

The wet season from October through April brings 1,200mm of the valley's annual 1,600mm precipitation. Monthly fresh water rinses during these months prevent mineral buildup from rainfall.

Garden hose spray provides sufficient water volume. Avoid pressure washers, which can force water into mounting hardware joints and damage sealants. Gentle rinsing removes minerals before they etch glass surfaces.

The process takes 10-15 minutes for typical deck installations. Start at the top and work downward, allowing water to carry minerals away from mounting points.

Monthly rinsing benefits include:

Prevents mineral buildup - removes deposits before etching occurs

Protects hardware - washes away corrosive elements

Maintains clarity - keeps glass transparent

Minimal time investment - 10-15 minutes monthly

Quarterly Deep Cleaning

Every three months, glass panels benefit from deeper cleaning with mild solutions. This removes stubborn water spots, pollen, and accumulated grime that rinsing alone cannot eliminate.

Mix mild dish soap or white vinegar with warm water. Apply with soft microfiber cloths only. Abrasive materials scratch glass surfaces and damage protective coatings.

Squeegee glass after washing to prevent water spots. Work from top to bottom in overlapping strokes. Dry mounting hardware with clean cloths to prevent mineral deposits.

Inspect hardware during quarterly cleaning. Look for early corrosion signs on stainless steel fasteners. Check sealants for any cracking or separation. Early detection prevents expensive repairs.

Quarterly cleaning includes:

Mild cleaning solutions - dish soap or vinegar and water

Soft materials only - microfiber cloths prevent scratching

Squeegee technique - eliminates water spots

Hardware inspection - catches issues early

Annual Professional Inspection

Once yearly, thorough inspection verifies structural integrity and identifies maintenance needs. This check catches small issues before they become expensive problems.

Check all mounting points for any movement or shifting. Properly installed systems remain rock-solid. Any detected movement requires immediate professional assessment.

Verify sealants remain intact around mounting hardware. Cracks or separation allow water infiltration that compromises structural mounting. Sealant replacement is simple when caught early.

Inspect stainless steel hardware for any corrosion signs. Even marine-grade materials benefit from inspection in coastal-influenced environments. Early treatment prevents spreading.

Annual inspection covers:

Mounting stability - no movement or shifting

Sealant integrity - no cracks or separation

Hardware condition - corrosion-free surfaces

Glass condition - no chips or cracks

For comprehensive maintenance protocols, review our coastal BC cleaning guide.

Why Abbotsford Is Tenmar's Fraser Valley Service Hub

Geographic positioning makes Abbotsford the natural center for glass railing services across the Fraser Valley. Understanding this relationship explains how regional service delivers local quality.

Central Location Serving the Entire Fraser Valley

Abbotsford holds official recognition as "the Hub of the Fraser Valley" from the Abbotsford Chamber of Commerce (2016). This designation reflects the city's central position connecting communities from Vancouver to Hope.

The population of 153,524 represents 3.3% annual growth (Statistics Canada, 2024). This expansion creates growing demand for quality home improvement services including glass railing installation.

Central access to Highway 1, Highway 7, and Highway 11 enables efficient service delivery across the region. Travel times from Abbotsford reach most Fraser Valley communities within 30-45 minutes.

Tenmar's base in Agassiz sits approximately 40 minutes east of Abbotsford via Highway 1 (Rome2Rio, 2024). This proximity makes Abbotsford the primary market hub for serving the entire Fraser Valley corridor.

Hub advantages include:

Official designation - recognized Fraser Valley economic center

Population growth - expanding market for services

Highway connectivity - efficient access across region

Strategic position - central location serves all communities

Regional Infrastructure Advantages

Abbotsford's infrastructure supports its role as Fraser Valley's hub. Regional facilities create economic vitality and attract skilled workers.

Abbotsford International Airport serves one million passengers annually (City of Abbotsford, 2024). This connectivity supports business operations and material sourcing.

University of the Fraser Valley provides skilled workforce development. Educational programs create the trained professionals that support quality construction services.

Abbotsford Regional Hospital and Cancer Centre serves the entire Fraser Valley. This regional medical facility demonstrates Abbotsford's role beyond city boundaries.

Provincial Supreme Court presence reflects governmental recognition of Abbotsford's regional importance. Services centralized here serve populations across multiple communities.

Infrastructure elements include:

International airport - one million annual passengers

Regional university - skilled workforce development

Hospital and cancer centre - valley-wide medical services

Provincial courthouse - regional governmental services

Serving Abbotsford and Surrounding Communities

Tenmar's service area extends throughout the Fraser Valley from Abbotsford as the central hub. Personal owner involvement characterizes every project despite geographic range.

Primary service communities include Chilliwack, Mission, and Langley. Each receives the same quality standards and personal attention.

Extended service reaches into Greater Vancouver and throughout the broader Fraser Valley region. Distance does not compromise quality or owner involvement.

Every project includes personal measurement by the owner. This hands-on approach ensures accuracy and allows direct communication about preferences and requirements.

Installation follows the same standards from Agassiz to Vancouver. BC Building Code compliance, quality materials, and climate-appropriate engineering apply equally across all locations.

Service area characteristics:

Fraser Valley focus - primary market served from Abbotsford hub

Consistent quality - same standards all locations

Personal involvement - owner measures every project

Regional reach - Agassiz to Greater Vancouver

Frequently Asked Questions

How long does glass railing installation take in Abbotsford?

Glass railing projects typically require 6-8 weeks from initial measurement to final installation. This timeline includes engineering review (1-2 weeks), fabrication (2-3 weeks), permitting if required (1-2 weeks), and installation (1-2 weeks). Complex projects with custom curved glass may extend to 8-10 weeks.

Do I need a building permit for glass railings in Abbotsford?

Most glass railing installations require a building permit when the deck or balcony is more than 600mm above grade. The BC Building Code 2024 mandates guard compliance for all elevated platforms. Abbotsford building inspectors verify installations meet current code standards during final inspection.

What's the difference between frameless and semi-frameless glass railings?

Frameless systems have no visible top rail, providing maximum views but requiring engineer-sealed drawings for BC Building Code compliance. Semi-frameless systems include aluminum posts (spaced maximum 42 inches apart) and a top rail, offering easier code compliance and simplified installation. Review our detailed comparison guide for complete analysis.

How do glass railings perform in Fraser Valley's rainy climate?

Glass railings excel in the Fraser Valley's wet climate. The material sheds water naturally without absorption, preventing the rot and deterioration that affect wood railings. Proper installation with drainage design and marine-grade hardware ensures decades of performance despite 1,600mm annual rainfall. Monthly rinsing during wet months maintains clarity and prevents mineral buildup.

Can glass railings withstand Abbotsford's freeze-thaw cycles?

Yes, when properly installed with quality materials. Marine-grade 316 stainless steel hardware resists expansion and contraction during freeze-thaw cycles between November and March. Glass itself remains unaffected by temperature fluctuations. Proper sealant selection maintains flexibility through temperature changes, preserving weather-tight connections.

How often do glass railings need cleaning in Abbotsford?

Monthly fresh water rinses during wet months (October through April) prevent mineral buildup from rainfall. Quarterly deep cleaning with mild soap maintains clarity and removes stubborn deposits. Annual professional inspection verifies structural integrity and catches maintenance needs early. This minimal maintenance schedule far exceeds wood railings that require annual staining and treatment. See our coastal BC cleaning guide for detailed protocols.

Do glass railings meet BC Building Code requirements?

Yes, when properly designed and installed. Glass must conform to CAN/CGSB-12.1-M90 safety standards for Tempered or Laminated Safety Glass (Government of Canada, 2016). Frameless systems require engineer-sealed shop drawings per BC Building Code 2024 Section 9.6. All installations must meet minimum height requirements: 900mm for decks up to 1.8m elevation, or 1,070mm for higher platforms.

What glass railing system is best for my Abbotsford property?

The best system depends on your priorities. Frameless systems maximize views and suit modern architecture but require engineering and premium investment. Semi-frameless systems balance aesthetics with budget considerations while simplifying code compliance. Curved systems accommodate unique architectural features but demand custom fabrication. Contact us for a free consultation and personalized recommendations for your property.

Key Takeaways

Understanding glass railings in Abbotsford's context helps homeowners make informed decisions. Four essential points summarize this guide:

Abbotsford's position as the Hub of the Fraser Valley provides central access to professional glass railing services across the region, with quality standards maintained from Agassiz to Greater Vancouver

Fraser Valley's 1,600mm annual precipitation makes glass the ideal low-maintenance choice compared to wood or traditional metal railings that deteriorate in wet conditions (BC Climate Change Adaptation Program, 2023)

Three main systems serve different needs: frameless for maximum views, semi-frameless for budget-conscious projects, and curved for unique architectural features, all requiring 6-8 week installation timelines

BC Building Code 2024 compliance requires guards when drops exceed 600mm, with minimum heights of 900mm or 1,070mm depending on elevation, and glass must meet CAN/CGSB-12.1-M90 safety standards (BC Building Code 2024, 2024)

Get Your Glass Railing Project Started

For glass railing design, engineering, and installation throughout Abbotsford and the Fraser Valley, contact Tenmar Contracting. Every project includes personal measurement, BC Building Code compliance verification, and installation designed specifically for Fraser Valley's unique climate conditions.

Explore our services in Abbotsford and surrounding Fraser Valley communities.