Glass Railing Applications Guide: Indoor, Outdoor & Property-Specific Solutions for BC Homes

Jan 27, 2026

Introduction

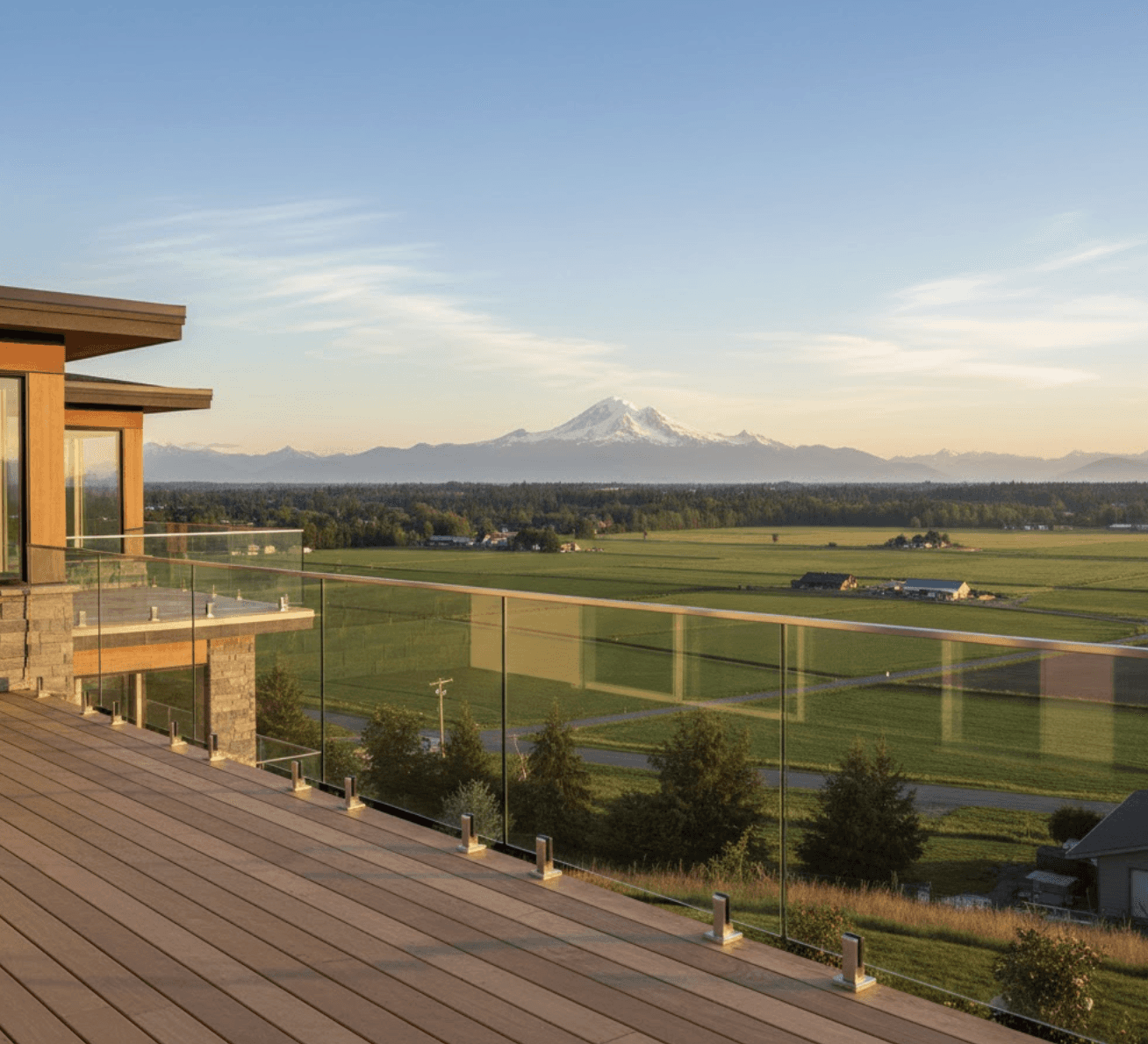

Glass railings transform BC properties by combining safety with unobstructed views of mountains, water, and urban landscapes. Whether you're planning a deck renovation in Fraser Valley or designing a custom home in Vancouver, understanding glass railing applications helps you choose the right system for your specific needs.

Different applications require different approaches. A second-storey deck overlooking Howe Sound has different requirements than an interior staircase in a Burnaby townhouse. Coastal properties within sight of the Pacific need different materials than homes in Abbotsford. This guide covers every major glass railing application, from residential decks to commercial buildings, with specific considerations for BC's coastal climate.

What this guide covers:

Outdoor vs indoor glass railing applications and their specific requirements

System types by application (frameless, semi-frameless, base shoe mounting)

Property-specific considerations (residential, multi-family, commercial, custom homes)

BC coastal climate factors affecting material selection

Building code compliance requirements for different applications

Understanding these distinctions ensures you select a system that meets safety codes, withstands BC's weather, and delivers the aesthetic you want.

Understanding Glass Railing Systems: Types and Mounting Methods

Before diving into specific applications, understanding the three main system types helps you make informed decisions. Each system type suits different applications based on view priorities, budget, and installation requirements.

Frameless Glass Railing Systems

Frameless systems use minimal hardware to create unobstructed views. Glass panels are secured directly to deck or floor surfaces using spigot mounting, standoff mounting, or base shoe channels. No vertical posts interrupt sightlines.

These systems typically require 12mm laminated glass in BC applications to meet provincial building code requirements (Glass Railing Store, 2024). Frameless installations require engineer-sealed shop drawings in BC to verify load capacity and glass specifications per CAN/CGSB standards (Tenmar, 2024).

Best applications for frameless systems:

Waterfront properties preserving ocean, lake, or river views

Mountain-view decks and balconies

High-rise condo balconies

Luxury custom homes where view preservation is priority

Properties where unobstructed sightlines justify premium investment

Key requirements:

Laminated safety glass (typically 12mm minimum)

Professional engineering and installation

Higher material costs (laminated glass costs 50-100% more than tempered glass) (San Diego Cable Railings, 2024)

Not recommended for DIY installation

Learn more about frameless glass balcony systems

Semi-Frameless Glass Railing Systems

Semi-frameless systems combine aluminum posts at regular intervals (maximum 42 inches apart in BC) with glass infill panels. Posts provide structural support while glass panels between them preserve views.

These systems offer flexibility in glass choice. Many applications allow standard 12mm tempered glass rather than requiring laminated glass, reducing material costs. Powder-coated aluminum posts resist corrosion and provide multiple finish options to match exterior colours.

Best applications for semi-frameless:

Standard residential decks and balconies

Commercial properties requiring durability

Multi-family and condo installations needing consistent appearance

Properties balancing view preservation with budget considerations

Fraser Valley homes with moderate coastal exposure

Advantages over frameless:

Lower material costs (tempered glass acceptable in many applications)

Easier installation process

Additional structural support from posts

Variety of post finishes and colours available

More suitable for capable DIY homeowners (though professional installation recommended)

Explore aluminum glass railing options

Mounting Methods Explained

Understanding mounting methods helps you select the right approach for your specific application:

Base Shoe / U-Channel Systems: Glass panels slot into a continuous aluminum channel mounted at the base. Water drains through the channel system, making this method ideal for BC's rainy climate. Top rail is optional depending on design preferences and code requirements.

Spigot Mounting: Glass panels are clamped between pairs of spigots surface-mounted to the deck. This creates a clean, modern aesthetic with minimal hardware visibility. Popular for frameless applications where view preservation is priority.

Standoff Mounting: Glass is anchored to the deck face using pairs of stainless steel or powder-coated standoffs. This method allows some visual separation between glass and deck surface, creating a floating appearance.

Post-Mounted Systems: Traditional approach where glass panels are secured within aluminum posts. Posts provide maximum structural support and are standard in semi-frameless applications.

Mounting strength considerations: Fascia mounting (attaching to the beam ends and sides) generally provides stronger support than deck surface mounting because beam sides and ends are structurally more robust than deck surfaces (eGlass Railing Systems, 2024). For elevated applications and high-wind areas like waterfront properties, fascia mounting is often preferred.

Outdoor Glass Railing Applications for BC Properties

Outdoor applications must withstand BC's coastal climate while preserving views and meeting building code requirements. From waterfront decks to mountain-view balconies, exterior systems require weather-resistant materials and proper installation.

Deck Glass Railings

Deck glass railings represent the most common outdoor application in BC properties. Second-storey decks, ground-level patios, and rooftop terraces all benefit from glass systems that preserve views while meeting safety requirements.

BC Building Code requirements for decks:

Guards required where drop exceeds 600mm (24 inches) (Glass Railing Store, 2024)

Minimum height: 900mm (36 inches) for decks up to 1.8m above grade (Tenmar, 2024)

Height increases to 1,070mm (42 inches) for decks higher than 1.8m (Tenmar, 2024)

Maximum opening size: 100mm (4 inches) between panels to prevent child passage (Glass Railing Store, 2024)

System recommendations by deck application:

Second-storey decks with mountain or water views: Frameless glass railing systems maximize vista preservation. These systems work best when the view justifies the premium cost. North Vancouver, West Vancouver, and Fraser Valley properties with mountain backdrops benefit significantly from unobstructed sightlines.

Standard residential decks: Semi-frameless systems with powder-coated aluminum posts balance view preservation with cost-effectiveness. These systems are more accessible for renovation projects and offer excellent durability in BC's climate.

Ground-level or low-elevation decks: Base shoe systems with tempered glass provide clean lines and excellent water drainage. The continuous bottom channel handles BC's rainfall efficiently while maintaining modern aesthetics.

Deck mounting considerations: Fraser Valley's rainfall makes drainage critical. Base shoe systems excel in wet climates with integrated drainage channels. For fascia-mounted systems, proper flashing prevents water intrusion at mounting points.

Professional deck railing installation services ensure code compliance and proper waterproofing.

Balcony Glass Railings

Balcony applications range from single-family home Juliet balconies to high-rise condo installations. Vancouver and Burnaby multi-family properties increasingly specify glass railings for modern aesthetics and code compliance.

Balcony-specific requirements:

Wind load calculations for elevated installations

Building code compliance for multi-family properties (often following commercial 1,070mm/42" requirements)

Waterproofing at mounting points critical for building envelope integrity

Strata approval considerations for condo replacements

Popular balcony systems:

High-rise balconies: Frameless spigot-mounted systems provide unobstructed city, mountain, or water views. These systems must meet higher wind load requirements, with calculations provided by professional engineers.

Low-rise and townhouse balconies: Semi-frameless systems offer durability and easier installation while maintaining modern aesthetics. These systems work well for townhouse and row home applications.

Juliet balconies: Minimal frameless systems with surface-mounted spigots create architectural statements on custom homes. These typically don't require full guard height since they're not walk-out balconies.

Patio and Ground-Level Applications

Patio glass railings serve both safety and aesthetic functions. Ground-level patios may not require guards under BC code if there's no drop exceeding 600mm, but property owners often install glass railings for wind protection, privacy, or design continuity.

When patios require guards: Any elevation change exceeding 600mm (24 inches) triggers guard requirements. This includes patios with sunken seating areas, terraced yards, or transitions to lower levels.

When patios don't require guards (but benefit from glass): Level patios can use glass systems for:

Wind protection in coastal areas (White Rock, North Vancouver waterfront)

Privacy screening without obstructing views

Defining outdoor spaces architecturally

Creating visual continuity with interior design

System options for patios: Glass fence panels work well for property line applications, providing privacy while maintaining openness. Low-profile base shoe systems integrate seamlessly with patio surfaces.

Pool Area Glass Railings

Pool area glass railings must meet specific BC safety requirements while providing clear sightlines for supervision. Frameless systems are popular for pool enclosures as they maintain visibility while preventing unauthorized access.

BC pool enclosure requirements:

Minimum height: 1,500mm (59 inches) throughout the Fraser Valley region (Glass Railing Store, 2024)

Some municipalities like Abbotsford require 1,200mm (47 inches) (Glass Railing Store, 2024)

No openings exceeding 100mm to prevent child access (Glass Railing Store, 2024)

Non-climbable design (glass panels excel here)

Self-closing, self-latching gates required

Glass specifications for pools:

Tempered or laminated safety glass minimum 12mm thick (Glass Railing Store, 2024)

Laminated glass preferred for post-break safety

Glass must meet CAN/CGSB-12.1-M90 safety glazing standards

Material considerations for pool environments:

Chlorine-resistant hardware for indoor pools (316 stainless steel)

Corrosion-resistant finishes for outdoor pools

Powder-coated aluminum posts with AAMA 2605 finish resist pool chemicals and coastal exposure

Waterfront & Coastal Property Applications

Waterfront properties in White Rock, North Vancouver, and coastal Fraser Valley require specialized material selection to withstand saltwater corrosion.

Coastal corrosion zones by distance from shoreline: Research shows the highest coastal corrosion rates occur within 400-600 meters (1,300-2,000 feet) of the shoreline, rising exponentially within 50-200 meters (165-650 feet) of shore (International Molybdenum Association, 2024).

Material requirements for coastal applications:

Within 200m of saltwater (extreme exposure zone):

316 stainless steel hardware minimum (contains 2-3% molybdenum for superior saltwater resistance) (Dahlstrom Rollform, 2024)

Consider 2205 duplex stainless steel for premium applications (PREN score of 34 provides full saltwater resistance) (Viewrail, 2024)

Laminated glass for wind and coastal building code requirements

All exposed fasteners must be marine-grade

200-600m from saltwater (high exposure zone):

316 stainless steel recommended

Quality powder-coated aluminum acceptable with AAMA 2605 finish (10-year warranty protection) (RailFX, 2024)

Regular freshwater rinsing extends hardware lifespan

Electropolished or brushed stainless finishes minimize chloride accumulation

Beyond 600m (moderate exposure):

Powder-coated aluminum with AAMA 2605 finish performs excellently (20+ year lifespan) (Hugh Aluminum, 2024)

304 stainless steel acceptable but requires more frequent cleaning to prevent surface staining (Dahlstrom Rollform, 2024)

Standard corrosion protection measures sufficient

Grade 304 vs 316 stainless steel performance: While 304 stainless steel is the most popular grade overall, it's susceptible to corrosion in saline coastal environments. It still has 1/10th to 1/100th the corrosion rate of common aluminum alloys, but requires frequent cleaning to prevent surface staining (Dahlstrom Rollform, 2024). For coastal applications, the premium for 316 stainless (2-3% molybdenum content) provides better long-term value.

Best practices for corrosion-resistant coastal installations:

Specify marine-grade hardware for all properties within 1km of saltwater

Regular freshwater rinsing removes salt deposits

Annual inspection of hardware and mounting points

Immediate replacement of any corroding components prevents accelerated degradation

Indoor Glass Railing Applications

Indoor glass railing applications maximize natural light flow and create open, connected spaces. From staircases to mezzanines, interior systems emphasize aesthetics while meeting safety requirements with more flexibility than exterior applications.

Interior Staircase Railings

Interior glass stair railings are the most common indoor application, serving both safety and design functions. Custom homes in Fraser Valley and Vancouver increasingly feature glass stair systems for modern aesthetics and spatial openness.

BC Building Code requirements for stairs:

Handrail height: 865-965mm (34-38 inches) above stair nosing

Guard height: 900mm (36 inches) minimum measured vertically from stair tread

Graspable handrail required (can be mounted on glass or separate)

Continuous protection along full stair length

Stairs with 3 or more risers require handrails

System types for interior stairs:

Frameless glass with standoff mounting: Creates minimalist design with maximum transparency. Standoffs secure glass to stair stringers or adjacent walls. Separate handrail (wood, metal, or glass-mounted) provides required graspability.

Post-supported glass infill: Traditional aesthetic with modern glass panels. Aluminum or steel posts provide structural support with glass secured between. Works well in homes balancing contemporary and classic design.

Curved glass systems: Custom solution for spiral or curved staircases. Requires specialty fabrication and engineering but creates stunning architectural statements in luxury custom homes.

Base shoe mounted stair railings: Continuous glass line from bottom to top of staircase. Clean, modern aesthetic popular in open-concept homes.

Design considerations for interior stairs:

Tempered glass sufficient for most interior applications (laminated not typically required by code)

Integration with hardwood or metal handrails

LED lighting under handrail or in glass edge for dramatic effect

Alignment with open-concept main floor design for visual flow

Custom stair railing solutions allow architectural creativity while meeting code requirements.

Mezzanines and Loft Railings

Mezzanines and lofts benefit significantly from glass railings that maintain visual connection between levels while allowing natural light to penetrate throughout the space. These applications are popular in modern Fraser Valley homes with vaulted ceilings and multi-level layouts.

Mezzanine guard requirements:

Load requirements identical to standard guards (200 lb concentrated load minimum, 50 plf uniform horizontal load) (Greco Railings, 2024)

Height requirements: 900mm (36 inches) minimum in residential, 1,070mm (42 inches) for commercial lofts (Greco Railings, 2024)

Same opening restrictions apply (100mm maximum)

Design advantages of glass on mezzanines:

Natural light reaches lower levels unobstructed

Maintains open, spacious feeling across multiple floors

Showcases architectural features and ceiling heights

Creates cohesive design language across levels

Cable or glass infill preserves visual openness better than picket systems

Applications in residential properties: Open-concept great rooms, home offices overlooking living spaces, loft bedrooms, and bonus rooms above kitchens all benefit from glass railing systems.

Basement Stair & Walkout Applications

Basement applications range from standard staircase guards to walkout patio transitions. Fraser Valley properties with walkout basements benefit from glass railings that create seamless indoor-outdoor flow.

Basement-specific applications:

Stairway guards (standard height and load requirements apply)

Walkout transitions to lower patio or yard

Basement suite separations (must be building code compliant for rental units)

Window well guards where required by code

System recommendations:

Standard tempered glass sufficient for interior basement stairs

Exterior-rated systems for walkout transitions

Powder-coated aluminum for below-grade applications resists moisture better than painted steel

Proper drainage at walkout thresholds critical in BC's wet climate

Glass Railing Applications by Property Type

Different property types have distinct requirements for glass railing applications. Understanding these differences ensures code compliance, appropriate system selection, and optimal performance for your building type.

Single-Family Residential Applications

Single-family homes offer the most flexibility in glass railing selection. Homeowners can choose systems based primarily on aesthetics, budget, and view preservation without complex approval processes required for multi-family buildings.

Residential application opportunities:

Front entry stairs and porches

Main and second-storey decks

Interior staircases and open-concept guards

Pool enclosures and spa surrounds

Balconies and Juliet balconies

Basement walkout transitions

BC residential code requirements:

900mm (36 inch) minimum guard height for decks up to 1.8m above grade (Tenmar, 2024)

1,070mm (42 inch) for decks and balconies above 1.8m (Tenmar, 2024)

600mm drop triggers guard requirement (Glass Railing Store, 2024)

100mm maximum opening between panels (Glass Railing Store, 2024)

System flexibility in residential: Homeowners can choose frameless, semi-frameless, or hybrid systems based on preferences. Tempered glass is acceptable for most interior applications. Laminated glass recommended for coastal or exposed exterior locations but not always required. Capable DIYers can tackle semi-frameless installations, though professional installation is recommended for safety and warranty protection.

Multi-Family & Condo Applications

Multi-family buildings and condominiums require glass railing systems meeting stricter code requirements, strata approval processes, and unified aesthetic standards across the property.

Multi-family specific requirements:

Often follow commercial building code standards (1,070mm/42 inch height minimum)

Strata council approval required for individual unit installations

Architect and engineer specifications for new construction

Consistent appearance across building units mandatory

Higher durability requirements for common areas

Common multi-family applications:

Individual condo balconies

Shared rooftop decks and terraces

Interior common area stairs and mezzanines

Townhouse front and rear decks

Pool area enclosures and amenity spaces

System recommendations: Semi-frameless with aluminum posts provide uniform appearance and cost-effectiveness for building-wide installations. Frameless systems appropriate for luxury condo buildings where premium aesthetics justify cost. Powder-coated finishes in strata-approved colours ensure consistency. Laminated glass often required for wind and safety requirements in taller buildings.

Approval considerations:

Strata design guidelines and approval timelines

Building envelope considerations (waterproofing critical)

Professional engineering certification required

Maintenance accessibility for high-rise applications

Warranty and service agreements for building-wide installations

Custom Homes and Luxury Properties

Custom homes and luxury properties use glass railings as architectural statement pieces, integrating premium materials and custom fabrication to achieve unique designs.

Premium material options:

2205 duplex stainless steel for ultimate coastal corrosion resistance (PREN score 34)

Custom curved glass for spiral staircases and radius applications

Oversized glass panels for maximum unobstructed views

Integrated LED lighting systems

Custom powder coat colours matching architectural finishes

Applications in luxury homes:

Grand entry staircases with curved or floating glass

Roof decks and penthouses with panoramic views

Wine cellars with glass guards

Indoor-outdoor seamless transitions

Infinity-edge pools with glass fencing

Engineering for custom applications: Complex designs require professional engineering regardless of property type. Custom curved glass, oversized panels, and unique mounting situations all demand engineer-sealed drawings showing load calculations and structural adequacy.

Commercial & Institutional Applications

Commercial and institutional properties require glass railing systems meeting stringent safety codes, high traffic durability, and accessibility requirements.

Commercial code requirements:

1,070mm (42 inch) minimum guard height throughout (Greco Railings, 2024)

Laminated glass required for most applications (IBC 2021 requirement) (Glass Railing Store, 2024)

Higher load requirements: 200 lb concentrated load plus 50 plf uniform horizontal load (Greco Railings, 2024)

Infill panels must resist 50 plf vertically in commercial applications (Greco Railings, 2024)

ADA/accessibility compliance where applicable

Often require fire-rated assemblies in certain locations

Commercial application types:

Office building atriums and mezzanines

Retail spaces and shopping centres

Restaurant patios and rooftop bars

Hotel balconies and terraces

Educational and institutional buildings

Mixed-use building common areas

System requirements:

Engineer-sealed designs mandatory

Tested and certified hardware systems

Laminated glass for fallout protection in areas above walkways

High-durability finishes resisting heavy use

Compliance with local commercial building codes

Maintenance considerations:

Durability for high-traffic public use

Easy cleaning in commercial spaces

Replacement part availability from manufacturers

Comprehensive warranties and professional support for commercial installations

Material Specifications for Different Applications In BC's Coastal Climate

BC's coastal environment demands careful material selection for outdoor glass railing applications. Saltwater exposure accelerates corrosion, making hardware choice critical for long-term performance.

Stainless steel grades for coastal applications:

304 Stainless Steel: The most popular stainless steel grade overall but susceptible to surface staining in coastal environments. Still has 1/10th to 1/100th the corrosion rate of aluminum alloys (Dahlstrom Rollform, 2024). Requires frequent cleaning (monthly or more often) to prevent discoloration. Acceptable for properties beyond 600m from saltwater with maintenance commitment.

316 Stainless Steel: Contains 2-3% molybdenum, significantly boosting corrosion resistance. Most commonly specified for coastal applications (Dahlstrom Rollform, 2024) between 200-600m from shore. Requires only periodic freshwater rinsing. Significantly better value than 304 for properties with regular salt air exposure.

2205 Duplex Stainless Steel: Premium option with PREN (Pitting Resistance Equivalent Number) score of 34, making it fully corrosion resistant to saltwater. Used in oil rigs and bridges over brackish water (Viewrail, 2024). Recommended for properties within 200m of shoreline or where maximum longevity justifies premium cost. Commonly available in posts, rods, and handrails.

Powder-coated aluminum performance: Quality powder-coated aluminum with AAMA 2605 finish provides 10-year warranty protection and 20+ year lifespan in coastal environments (RailFX, 2024) with minimal maintenance. This finish resists chipping, scratching, UV damage, and saltwater exposure. More economical than premium stainless steel while delivering excellent coastal performance.

Distance-based material recommendations:

Distance from Saltwater | Recommended Materials | Maintenance |

|---|---|---|

0-200m (Extreme) | 316+ stainless or 2205 duplex required | Monthly freshwater rinse |

200-400m (High) | 316 stainless minimum or powder-coated aluminum | Quarterly freshwater rinse |

400-600m (Moderate) | Powder-coated aluminum (AAMA 2605) or 316 stainless | Semi-annual cleaning |

600m+ (Standard coastal) | Powder-coated aluminum acceptable, 304 stainless with maintenance | Annual inspection |

Best practices for low-maintenance coastal glass railings:

Specify marine-grade hardware regardless of exact distance

Use electropolished or brushed stainless finishes (smooth surfaces resist chloride accumulation better than rougher finishes)

Avoid galvanic corrosion by matching metal types (don't combine stainless posts with aluminum components)

Regular freshwater rinsing removes salt deposits before corrosion begins

Annual professional inspection catches issues before they become major problems

Building Code Requirements for Glass Railing Applications in BC

Glass railing applications in BC must comply with the BC Building Code 2024, which specifies requirements for height, load capacity, glass type, and installation methods.

BC Building Code Basics

When guards are required: Guards must be installed where there is a drop of more than 600mm (24 inches) (Glass Railing Store, 2024). This triggers requirement applies to decks, balconies, stairs, ramps, and any elevated platform.

Height requirements by elevation:

Decks up to 1.8m (5 feet 10 inches) above grade: 900mm (36 inches) minimum (Tenmar, 2024)

Decks and balconies above 1.8m: 1,070mm (42 inches) minimum (Tenmar, 2024)

Commercial applications: 1,070mm (42 inches) regardless of elevation

Opening size restrictions: No opening in the guard may allow passage of a spherical object having a diameter of 100mm (approximately 4 inches) (Glass Railing Store, 2024). This prevents children from passing through or getting heads stuck between panels.

Glass thickness requirements: All glass panel railings must be at least 12mm (0.5 inches) thick for laminated or tempered safety glass meeting CAN/CGSB-12.1-M90 standards (Glass Railing Store, 2024).

2024 BC Building Code updates: The 2024 edition introduced updates for guard load resistance and glass design standards, reflecting seismic and wind-zone improvements (Tenmar, 2024). These revisions strengthen structural integrity and occupant safety, particularly for frameless and multi-panel systems used in contemporary homes.

For detailed BC Building Code requirements, see our complete guide: BC Building Code Requirements for Glass Railings

Residential vs Commercial Code Differences

Residential applications (IRC / BC Part 9):

900-1,070mm height depending on elevation

Tempered or laminated glass acceptable for many applications

200 lb concentrated load minimum

50 plf uniform horizontal load

Commercial applications (IBC / BC Part 3):

1,070mm (42 inch) minimum height throughout

Laminated glass increasingly required

Same 200 lb concentrated load requirement

50 plf uniform horizontal load plus 50 plf vertical load on infill panels

When multi-family follows commercial code: Multi-family buildings (condos, apartments) typically follow commercial building code requirements even though individual units are residences. This means 42-inch height minimum and often laminated glass requirements.

Permit and Engineering Requirements

When permits are required: Most glass railing installations require building permits in BC, especially for:

New deck construction with railings

Replacement railings on existing decks (verify with municipality)

Commercial applications (always require permits and inspections)

Any structural modifications

Permit costs and timeline:

Permit fees typically range from $200-$800 depending on project scope and municipality (Glass Railing Store, 2024)

Plan review: 2-6 weeks for approval

Inspections: Rough-in and final inspections required

Engineer-sealed drawings: Frameless or "topless" glass railing systems must include engineer-sealed shop drawings verifying load capacity and glass specification per CAN/CGSB standards in BC (Tenmar, 2024). Professional engineers must sign off that the system meets structural requirements before permits are issued.

Municipal variations: Vancouver, Burnaby, Surrey, Abbotsford, and other Fraser Valley municipalities each have specific requirements. Some enforce stricter standards than provincial code. Coastal municipalities may have additional wind load requirements. Always verify requirements with your local building department.

Installation Considerations by Application Type

Professional installation ensures code compliance, proper material selection for your climate zone, and long-term performance across all glass railing applications.

Deck Installation Specifics

Mounting surface compatibility: Glass railings can mount to wood, composite, concrete, or steel deck surfaces. Each requires specific fasteners and techniques. Pressure-treated lumber, cedar, and engineered lumber all accept glass railing mounts with proper hardware.

Fascia vs deck-top mounting: Fascia mounting (attaching to beam ends and sides) generally provides stronger support than deck surface mounting. Beam sides and ends are structurally more robust than deck surfaces. For elevated applications and high-wind coastal areas, fascia mounting is often preferred.

Structural support verification: Existing deck framing must be verified for adequate strength. Adding glass railings to older decks may require reinforcement. Joists, beams, and blocking must support guard loads (200 lb point load minimum). Professional installers evaluate existing structure before mounting.

Timeline for deck installations: Professional deck railing installation typically requires 1-3 days for average residential decks depending on complexity and system type. Custom fabrication adds 4-8 weeks to timelines.

Interior Staircase Installation

Handrail vs guard requirements: Stairs require both handrails (for grip during ascent/descent) and guards (for fall protection along open sides). Glass systems can incorporate both or use separate handrails mounted to glass or walls.

Code compliance complexity: Interior stair railing installations must navigate specific handrail height requirements (34-38 inches above nosing), graspability requirements, and guard height requirements simultaneously. Professional installers ensure all code requirements are met.

Custom fabrication for stairs: Stairs with winders, landings, or transitions require precise measurements and custom fabrication. Field measurements by experienced professionals ensure accurate fit. Most residential stair installations are custom-fabricated to exact specifications.

Why Professional Installation Matters

Code compliance assurance: Professional installers stay current on BC Building Code requirements and municipal variations. They ensure systems meet all height, load, glass type, and mounting requirements. Failed inspections delay projects and add costs.

Structural integrity: Proper load testing and structural calculations prevent failures. Glass railings must withstand real-world impacts, wind loads, and daily use. Professional engineering identifies potential weaknesses before installation.

Warranty protection: Manufacturer warranties typically require professional installation. DIY installations void warranties on glass and hardware. Professional installation provides recourse if issues develop.

Safety considerations: Glass panels weigh 30-60 pounds each. Laminated glass panels are particularly heavy. Professional installers have equipment, experience, and insurance to handle materials safely. Mounting hardware must be precisely positioned and torqued to specifications.

Material selection expertise: Coastal property owners benefit from installer knowledge about which materials perform best in specific exposure zones. Choosing between 304 and 316 stainless, powder coat specifications, and glass types requires experience with local conditions.

Maintenance and Longevity by Application

Understanding maintenance requirements helps you make informed decisions about glass railing investments and ensures long-term performance.

Outdoor Application Maintenance

Coastal property cleaning schedules:

Within 200m of saltwater: Monthly freshwater rinse

200-600m from saltwater: Quarterly cleaning

Beyond 600m: Semi-annual cleaning sufficient

Cleaning products and methods: Use mild soap and water for both glass and hardware. Avoid abrasive cleaners, bleach, or products containing chlorine (these damage stainless steel). Soft cloths or non-abrasive sponges prevent scratching. Rinse thoroughly after cleaning.

Seasonal maintenance: Pre-winter inspections catch small issues before freeze-thaw cycles cause damage. Check mounting hardware torque, sealant condition, and drainage channels. Clear debris from base shoe channels before winter.

Expected lifespan with proper care:

Powder-coated aluminum: 20-25 years in coastal environments (Hugh Aluminum, 2024), 30+ years inland

316 stainless steel: 25-30+ years in coastal areas with maintenance

2205 duplex stainless: 30-40+ years even in severe coastal exposure (Viewrail, 2024)

Glass panels (tempered or laminated): Indefinite lifespan with proper care

Quality low-maintenance glass railings require significantly less upkeep than wood railings (no staining/sealing) or painted metal systems (no repainting).

Indoor Application Maintenance

Minimal cleaning requirements: Interior glass railings require cleaning similar to windows. Wipe with glass cleaner or soap and water when smudges or fingerprints accumulate. Frequency depends on household use and visibility of marks.

Comparison to alternatives: Glass railings require less maintenance than wood (no refinishing), wrought iron (no rust protection), or cable systems (cables don't need periodic tensioning). Stainless steel or powder-coated aluminum posts don't require painting or sealing.

Long-term durability indoors: Interior applications aren't exposed to weather, UV, or corrosion. Properly installed systems last the lifetime of the home with minimal intervention beyond occasional cleaning.

Cost Considerations by Application Type

Understanding cost factors helps you budget appropriately and make value-based decisions for your specific application.

Cost Variables Affecting All Applications

System type impact: Frameless systems cost more than semi-frameless due to laminated glass requirements (50-100% premium over tempered), engineering costs, and more complex installation. Semi-frameless systems offer significant savings while still providing glass benefits.

Glass type costs:

Tempered glass: Base cost

Laminated glass: 50-100% premium over tempered

Curved or custom-shaped glass: Additional 100-200% premium for specialty fabrication

Linear footage: Longer runs reduce per-foot costs due to economies of scale in fabrication and installation. Very short runs (under 10 linear feet) carry higher per-foot costs.

Height requirements: Taller guards (commercial 42-inch vs residential 36-inch) require more glass and material, increasing costs proportionally.

Complexity factors:

Stairs cost more per linear foot than level runs

Curved applications require custom fabrication

Difficult access (rooftops, high-rise balconies) increases installation costs

Site conditions (remove existing railings, structural reinforcement) add costs

Long-Term Value and ROI

Minimal maintenance costs: Over a 20+ year lifespan, glass railings require minimal maintenance spending compared to wood (restaining every 2-3 years) or painted metal (repainting every 5-7 years). Annual cleaning costs are negligible (DIY or included in window cleaning services).

Home value impact: Modern glass railings increase property appeal and value, particularly for homes with views. Real estate professionals consistently cite unobstructed views as significant selling features. Glass railings that preserve views command premium pricing.

Avoided replacement costs: Quality glass railing systems last 20-30+ years without replacement. Wood railings may require replacement every 10-15 years. Metal railings need periodic refinishing. Properly specified glass systems are "install and forget" solutions.

Energy efficiency considerations: Interior glass railings allow natural light to flow through multi-level homes, reducing artificial lighting needs. Open-concept spaces with glass guards feel larger and brighter, reducing energy use.

Frequently Asked Questions

What is the difference between indoor and outdoor glass railings?

Outdoor glass railings require weather-resistant materials including marine-grade stainless steel hardware (316 grade minimum) or powder-coated aluminum with AAMA 2605 finish. Coastal BC areas often require laminated glass for exterior applications due to wind exposure and post-break safety. Indoor railings can use standard tempered glass in most applications and have more flexibility in hardware finishes, focusing primarily on aesthetics and code compliance for height and load requirements.

Are glass railings safe for residential use?

Yes, properly installed code-compliant glass railings are extremely safe. Modern building codes require tempered or laminated safety glass that is 5-7 times stronger than standard annealed glass. Systems must withstand minimum 200-pound concentrated loads and meet strict safety glazing standards under ANSI Z97.1 or CPSC 16 CFR 1201. Tempered glass breaks into small blunt pieces reducing injury risk, while laminated glass remains in place even when broken, maintaining the protective barrier.

Do glass railings meet BC Building Code requirements?

Yes, properly designed glass railing systems meet or exceed BC Building Code 2024 requirements. The code specifies minimum 12mm glass thickness, guard heights of 900-1,070mm depending on elevation, and maximum 100mm opening size between panels. Frameless systems require engineer-sealed drawings for code compliance. Both tempered and laminated glass are acceptable when they meet CAN/CGSB-12.1-M90 safety glazing standards, though laminated is increasingly required for specific applications.

How much maintenance do glass railings require?

Glass railings require minimal maintenance compared to wood or metal alternatives. Outdoor systems need periodic cleaning with mild soap and water, similar to window maintenance. Coastal BC properties require more frequent cleaning to remove salt deposits—monthly within 200m of shore, quarterly for properties 200-600m from saltwater. Properly specified materials like 316 stainless steel or powder-coated aluminum (AAMA 2605 finish) last 20+ years with this minimal care routine.

Can glass railings be used on stairs?

Yes, glass railings are ideal for both interior and exterior staircases. Stair applications must meet BC Building Code handrail requirements (865-965mm height, 34-38 inches) and include graspable handrails. The glass guard must be 900mm minimum height. Glass can be frameless with separate handrails or integrated into post systems. Professional installation ensures all code requirements are met including proper mounting to stair stringers and walls.

What types of glass are used for railings in BC?

BC Building Code allows tempered or laminated safety glass meeting CAN/CGSB-12.1-M90 standards, minimum 12mm thick. Tempered glass is heat-treated for 5-7 times greater strength and breaks into small blunt pieces for safety. Laminated glass uses a plastic interlayer bonding two glass layers—it stays intact when broken, providing continued fall protection. Coastal BC exterior applications increasingly require laminated glass for superior post-break performance and wind resistance. Interior applications typically allow tempered glass.

Are glass railings suitable for commercial buildings?

Yes, glass railings are widely used in commercial, institutional, and multi-family buildings. Commercial applications must meet IBC requirements including 1,070mm (42 inch) minimum height, higher load capacity (200 lb concentrated plus 50 plf uniform horizontal plus 50 plf vertical on infill), and laminated safety glass. These systems provide code-compliant safety while maintaining professional aesthetics and unobstructed views in office buildings, retail spaces, hotels, restaurants, and institutional facilities.

How does coastal climate affect glass railing choice in BC?

Coastal BC properties within 400-600 meters of saltwater experience significantly higher corrosion rates requiring specific material selection. Use 316 stainless steel hardware minimum (contains 2-3% molybdenum for saltwater resistance) rather than 304 stainless which shows surface staining. Powder-coated aluminum with AAMA 2605 coating provides 20+ year lifespan in coastal environments. Consider laminated glass for exterior coastal applications for superior wind and post-break performance. Properties within 200m of shore should specify 2205 duplex stainless steel or highest-grade powder coating for maximum longevity.

Summary: Choosing the Right Glass Railing Application for Your BC Property

Glass railing applications range from waterfront decks preserving ocean views to interior staircases enhancing natural light flow throughout multi-level homes. The right system depends on your specific application, property type, exposure to BC's coastal climate, budget, and aesthetic goals.

Key takeaways for BC property owners:

Application diversity: Glass railings serve both outdoor applications (decks, balconies, patios, pools) and indoor applications (staircases, mezzanines, lofts) with different system requirements, glass types, and code compliance needs for each

BC Building Code compliance: Guards are required for drops exceeding 600mm (24 inches). Height minimums are 900mm for decks up to 1.8m elevation and 1,070mm for higher decks and commercial applications. All glass must be minimum 12mm thick safety glass with maximum 100mm openings between panels

System selection by application: Frameless systems maximize mountain, water, and city views but require laminated glass and engineer-sealed drawings in BC. Semi-frameless systems balance view preservation with cost-effectiveness. Base shoe mounting systems excel in wet climates with integrated drainage handling BC's rainfall

Coastal climate considerations: Properties within 400-600m of shoreline require marine-grade hardware (316 stainless steel minimum or quality powder-coated aluminum). Coastal exposure zones determine material specifications. Proper material selection and regular maintenance extend performance to 20-30+ years even in saltwater environments

Property type requirements: Single-family homes have the most flexibility. Multi-family buildings require strata approval and often follow commercial code requirements. Commercial applications need stricter compliance including laminated glass and higher load capacity

Understanding these distinctions between applications, property types, and climate requirements helps you select glass railing systems that meet safety codes, withstand BC's weather patterns, and deliver the unobstructed views that make glass railings such valuable architectural features.

Professional installation ensures code compliance, proper material selection for your specific coastal exposure zone, and long-term performance. Whether you're planning a deck renovation in Fraser Valley, a custom home in Vancouver, or a commercial project in Burnaby, choosing the right glass railing application creates lasting value through safety, durability, and view preservation.

Ready to explore glass railing solutions for your specific application? Contact Tenmar for a consultation and site assessment. Our team specializes in BC Building Code-compliant installations across Metro Vancouver and Fraser Valley, with expertise in material selection for coastal properties and custom applications.

Schedule a consultation | View our application portfolio | Explore who we serve