Glass Railings in Vancouver & Fraser Valley: Complete Installation Guide for BC Properties

Jan 27, 2026

Introduction

Your location in Metro Vancouver or Fraser Valley significantly impacts which glass railing system performs best for your property. A waterfront home in White Rock requires different materials than an inland property in Abbotsford. Coastal North Vancouver installations face saltwater exposure that doesn't affect homes in Langley. Even permit processes and installation timelines vary between Vancouver, Surrey, and Fraser Valley municipalities.

This guide provides location-specific recommendations for glass railing installations across Metro Vancouver and Fraser Valley. Whether you're planning a deck renovation in Vancouver, a waterfront project in North Vancouver, or a custom home in Abbotsford, understanding your local requirements ensures proper material selection, code compliance, and long-term performance.

What this location-specific guide covers:

Coastal exposure zones mapped to Metro Vancouver and Fraser Valley municipalities

Material recommendations by distance from saltwater (0-200m vs 600m+ zones)

Municipality-specific permit processes and timelines

Regional cost differences (Vancouver premium vs Fraser Valley standard pricing)

Seasonal installation timing for BC's wet climate

Building code compliance across different municipalities

For application-specific guidance (decks, stairs, balconies, pools), see our Complete Guide to Glass Railing Applications.

Understanding Metro Vancouver's Coastal Climate & Geography

Metro Vancouver's proximity to the Pacific Ocean creates distinct coastal exposure zones that determine which materials perform best for glass railing installations. Properties within meters of saltwater require different hardware specifications than homes kilometers inland.

Saltwater Exposure Zones Across Metro Vancouver

Research shows the highest coastal corrosion rates occur within 400-600 meters (1,300-2,000 feet) of the shoreline, rising exponentially within 50-200 meters (165-650 feet) of shore (International Molybdenum Association, 2024).

Geographic application to BC municipalities:

Extreme Exposure Zone (0-200m from saltwater):

White Rock beachfront properties

North Vancouver waterfront estates along Burrard Inlet

Tsawwassen beach areas

Point Roberts adjacent properties

High Exposure Zone (200-600m from saltwater):

Most of White Rock residential areas

North Vancouver and West Vancouver coastal neighborhoods

Richmond waterfront properties

Delta coastal areas

Portions of Vancouver near False Creek and English Bay

Moderate Exposure Zone (600m-2km from saltwater):

Most of Vancouver city proper

Burnaby (majority of municipality)

Inland Richmond and Delta neighborhoods

Inland Zone (2km+ from saltwater):

Entire Fraser Valley region

Surrey (majority of municipality)

Maple Ridge and Mission

Rainfall and Moisture Considerations

Vancouver receives significant annual rainfall with wettest months October through March (Weather Stats, 2026). This wet climate affects installation timing, drainage system importance, and sealant curing requirements.

Proper drainage becomes critical across all BC locations. Base shoe mounting systems with integrated water channels perform exceptionally well in BC's wet climate, preventing water accumulation that could compromise mounting integrity or cause premature corrosion.

Glass Railings in Vancouver (City of Vancouver)

Vancouver presents unique considerations for glass railing installations, from high-density urban environments to heritage districts with specific design requirements.

Downtown & Urban High-Rise Applications

Vancouver's concentration of high-rise residential and commercial buildings creates demand for frameless glass systems that maximize city, mountain, and water views. Multi-family and condo installations typically follow commercial building code requirements even though units are residences.

Commercial and multi-family buildings often require laminated glass by code (Glass Railing Store, 2024). Frameless glass railing systems without top rails require laminated glass (IBC 2021 requirement) (Greco Railings, 2024). This applies to most Vancouver condo balconies and creates material cost considerations.

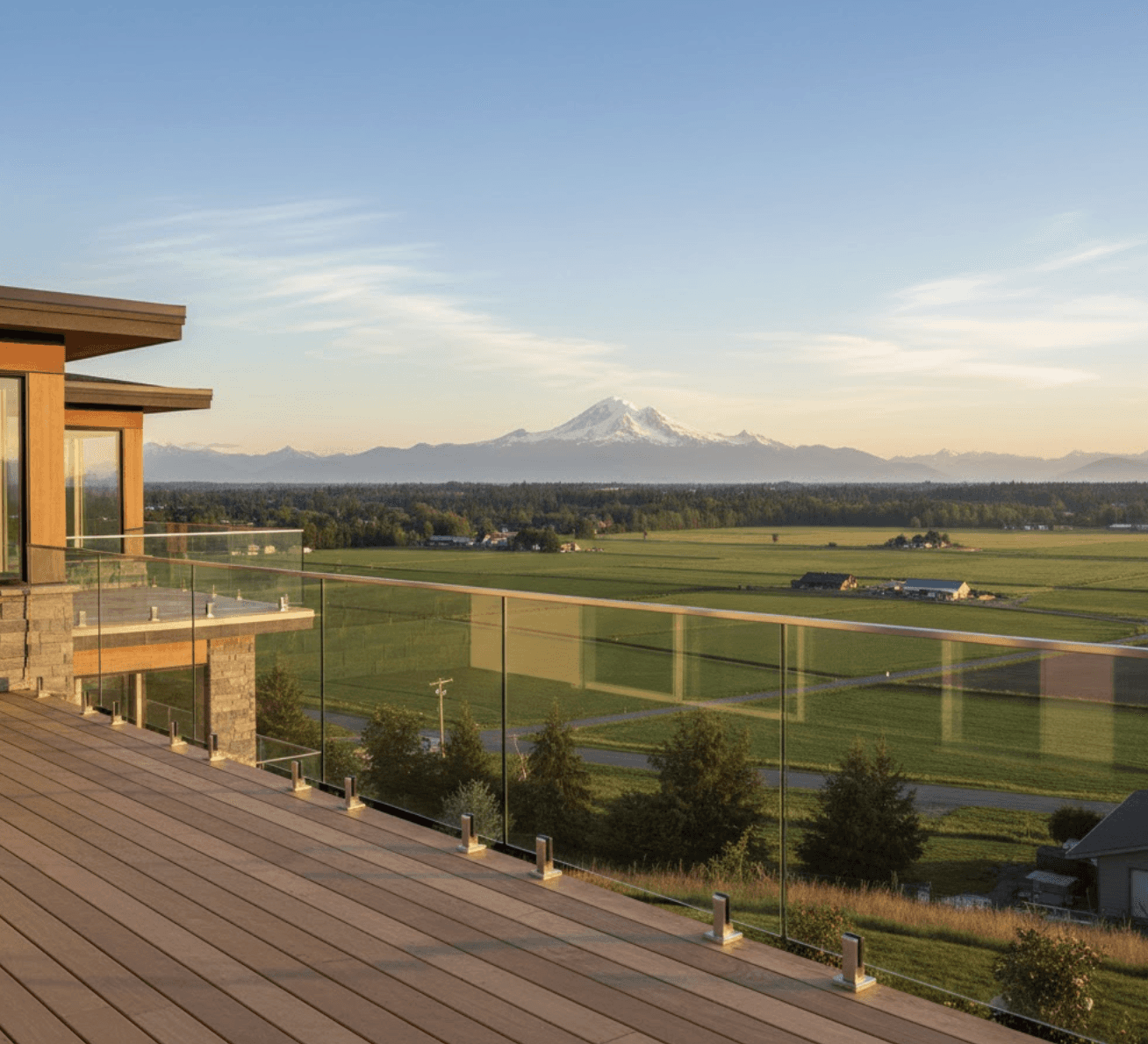

View Preservation in Vancouver Properties

Vancouver properties command premium prices partly due to views of mountains, water, and city skyline. Frameless glass balcony systems preserve these views without visual interruption from posts. Despite the premium cost (laminated glass costs 50-100% more than tempered glass) (San Diego Cable Railings, 2024), view preservation often justifies the investment for Vancouver properties.

Permit Process and Building Department

Vancouver building permit processes typically require 4-8 weeks for plan review and approval. Building permit fees typically range from $200-$800 depending on project scope and municipality (Glass Railing Store, 2024), with Vancouver tending toward the higher end of this range.

Frameless or "topless" glass railing systems must include engineer-sealed shop drawings verifying load capacity and glass specification per CAN/CGSB standards in BC (Tenmar, 2024). Professional engineers must sign off that systems meet structural requirements before permits are issued.

Heritage districts and certain Vancouver neighborhoods may have additional design review requirements. Properties in these areas should consult with the Vancouver Heritage Conservation Program early in planning stages.

Cost Considerations in Vancouver

Vancouver glass railing installations typically cost 15-25% more than Fraser Valley projects due to higher labor costs, stricter permitting requirements, and urban access challenges. Downtown high-rise projects face additional costs for parking permits, material hoisting, and restricted work hours.

North Shore Glass Railings (North Vancouver & West Vancouver)

North Shore properties combine coastal exposure with premium mountain and water views, creating unique requirements for glass railing systems.

Waterfront Property Material Requirements

North Shore coastal properties fall primarily within the high exposure zone (100-600m from Burrard Inlet and Howe Sound). Properties this close to saltwater require marine-grade materials for long-term performance.

316 stainless steel contains 2-3% molybdenum for superior saltwater resistance (Dahlstrom Rollform, 2024). This makes it the minimum specification for North Shore waterfront installations. Alternatively, quality powder-coated aluminum with AAMA 2605 finish provides 10-year warranty protection and 20+ year lifespan in coastal environments (RailFX, 2024).

For extreme waterfront exposure (properties within 200m of shore), consider 2205 duplex stainless steel. This premium option has a PREN (Pitting Resistance Equivalent Number) score of 34, making it fully corrosion resistant to saltwater (Viewrail, 2024). Used in oil rigs and bridges over brackish water, 2205 duplex provides 30-40+ year lifespan even in severe coastal exposure (Viewrail, 2024).

Mountain View Preservation Strategies

North Shore hillside properties often feature dramatic mountain and city views. Frameless glass systems maximize these vistas without posts interrupting sightlines. Many custom homes and luxury properties on the North Shore prioritize view preservation over cost considerations.

Mountain view glass railing applications benefit from professional engineering that accounts for both structural requirements and aesthetic goals. Custom curved glass and oversized panels create architectural statements while meeting BC Building Code requirements.

Wind Load and Engineering Considerations

North Shore elevated and exposed properties face higher wind loads than sheltered locations. BC Building Code wind zones require enhanced calculations for hillside and waterfront installations. Fascia mounting (attaching to beam ends and sides) generally provides stronger support than deck surface mounting (eGlass Railing Systems, 2024), making it preferred for exposed North Shore decks.

Premium Installation Standards

North Shore properties typically expect premium materials, installation precision, and architectural integration. Permits take 4-8 weeks similar to Vancouver. Installation crews familiar with hillside access, waterfront exposure requirements, and luxury property expectations deliver best results.

Fraser Valley Glass Railing Installations

Fraser Valley municipalities offer different climate conditions and installation considerations than coastal Metro Vancouver.

Abbotsford Glass Railing Installations

Abbotsford represents inland Fraser Valley climate characteristics. Located approximately 70km from saltwater, properties face no coastal corrosion concerns. This creates material selection flexibility and cost advantages.

304 stainless steel, while susceptible to surface staining in coastal environments, performs excellently inland with 1/10th to 1/100th the corrosion rate of aluminum alloys (Dahlstrom Rollform, 2024). For Abbotsford installations, 304 stainless steel offers cost savings versus 316 grade without performance compromise.

Powder-coated aluminum with AAMA 2605 finish lasts 30+ years in inland environments (Hugh Aluminum, 2024), making it an excellent value proposition for Fraser Valley properties. The frameless glass deck railing systems in Abbotsford can use these cost-effective materials while delivering decades of maintenance-free performance.

Abbotsford building permits typically process in 2-4 weeks, faster than Vancouver's 4-8 week timeline. This allows quicker project completion from design to installation.

Langley & Surrey Considerations

Langley and Surrey bridge the transition between coastal Metro Vancouver and inland Fraser Valley. Most properties in these municipalities fall within the moderate inland zone (2km+ from saltwater), though some Surrey areas near Boundary Bay experience moderate coastal exposure.

Glass railing installation in Langley follows standard inland specifications with powder-coated aluminum or 304/316 stainless steel all performing well. Surrey installations should assess proximity to Boundary Bay and Mud Bay to determine if coastal-grade materials are warranted.

Both municipalities process permits in 3-6 weeks typically, falling between Vancouver's longer timelines and eastern Fraser Valley's faster processing.

Chilliwack & Eastern Fraser Valley

Chilliwack and eastern Fraser Valley municipalities experience the most extreme temperature variations in the region. Summers reach higher temperatures than Vancouver, winters drop colder. This temperature cycling affects sealant selection and curing requirements but doesn't create the corrosion challenges of coastal exposure.

All standard glass railing materials perform excellently in this climate. Powder-coated aluminum provides 30+ year lifespan. Tempered glass suffices for most residential applications. Costs run 15-25% below Vancouver rates due to lower labor costs and simpler permitting.

Permit processing in Chilliwack and eastern Fraser Valley typically completes in 2-4 weeks, among the fastest in the region.

Coastal Municipalities: White Rock, Richmond, Delta, Tsawwassen

Several Metro Vancouver municipalities face extreme or high saltwater exposure requiring specific material selections.

White Rock Waterfront Requirements

White Rock beachfront properties sit directly on Semiahmoo Bay, placing them in the extreme exposure zone (0-200m from ocean). Saltwater spray reaches these properties during storms, creating the harshest corrosion environment in Metro Vancouver.

Properties this close to saltwater require 316 stainless steel hardware minimum, though 2205 duplex stainless steel is strongly recommended. The 2-3% molybdenum content in 316 stainless significantly boosts corrosion resistance (Dahlstrom Rollform, 2024), while 2205 duplex's PREN score of 34 provides full saltwater resistance (Viewrail, 2024).

Laminated glass is recommended for exterior coastal applications due to wind resistance and post-break retention (Viewrail, 2024). White Rock's oceanfront exposure generates significant wind loads requiring enhanced glass specifications.

Monthly freshwater rinsing removes salt deposits before corrosion begins. Even marine-grade materials benefit from this simple maintenance routine. Waterfront glass railing installations in White Rock represent premium investments but deliver decades of performance when properly specified.

Richmond & Delta Coastal Considerations

Richmond and Delta properties vary widely in coastal exposure. Waterfront areas along the Fraser River, Strait of Georgia, and Boundary Bay fall within high exposure zones (200-600m from saltwater), while inland neighborhoods experience moderate to minimal exposure.

Waterfront properties should specify 316 stainless steel or AAMA 2605 powder-coated aluminum. Inland Richmond and Delta properties can use standard materials (304 stainless acceptable, powder-coated aluminum excellent).

Richmond's extensive waterfront development creates demand for corrosion-resistant glass railing solutions. Delta's mix of rural and developed areas means installation crews should assess each property's specific exposure before material specification.

Tsawwassen Beach Area Installations

Tsawwassen beach communities face direct Georgia Strait exposure similar to White Rock. Properties within sight of the water require extreme coastal material specifications: 316 stainless steel minimum, 2205 duplex recommended for beachfront.

The exposed position also creates wind load considerations requiring professional engineering. Laminated glass provides superior wind resistance versus tempered glass in these applications.

Marine-Grade Material Specifications

All coastal municipalities benefit from marine-grade hardware specifications even when not strictly required by distance calculations. The relatively small material premium (10-20% cost increase for 316 vs 304 stainless) provides significant peace of mind and extended lifespan.

Quality powder-coated aluminum with AAMA 2605 finish provides excellent coastal performance at lower cost than stainless steel. This makes it attractive for properties in the 200-600m exposure zone where premium stainless may exceed budget while standard 304 stainless requires excessive maintenance.

Other Metro Vancouver Municipalities

Several Metro Vancouver municipalities fall into moderate coastal exposure or inland categories with standard installation considerations.

Burnaby Glass Railing Installations

Burnaby sits inland from Vancouver's waterfront, placing most properties in the moderate exposure zone (800m-2km+ from saltwater). This allows standard material specifications with powder-coated aluminum performing excellently.

Burnaby's mix of residential, multi-family, and commercial properties creates diverse installation requirements. High-rise developments in Metrotown and Brentwood follow Vancouver's multi-family code requirements including laminated glass specifications.

Permit processing in Burnaby typically takes 3-6 weeks, falling between Vancouver's longer timelines and Fraser Valley's faster processing.

Tri-Cities: Coquitlam, Port Coquitlam, Port Moody

Coquitlam, Port Coquitlam, and Port Moody represent inland Metro Vancouver with minimal coastal exposure. Properties here enjoy material selection flexibility similar to Fraser Valley municipalities.

Standard powder-coated aluminum with AAMA 2605 finish provides 20-25 years in coastal environments (Hugh Aluminum, 2024) and 30+ years in these inland locations. This makes it the most cost-effective choice for Tri-Cities installations.

Permits process in 2-5 weeks across the Tri-Cities. Costs align with standard Metro Vancouver pricing, avoiding both the Vancouver premium and Fraser Valley discount.

New Westminster & Pitt Meadows

New Westminster sits along the Fraser River but far enough inland to avoid significant coastal exposure for most properties. Pitt Meadows experiences even less coastal influence.

Both municipalities allow standard material specifications with any quality powder-coated aluminum or stainless steel grade performing well. Permit timelines run 3-5 weeks. Costs align with standard Metro Vancouver rates.

Maple Ridge & Mission

Maple Ridge and Mission represent the eastern edge of Metro Vancouver, transitioning into Fraser Valley climate and cost characteristics. Properties here enjoy inland material flexibility, faster permit processing (2-5 weeks), and pricing closer to Fraser Valley standard rates than Vancouver premium.

Material Selection by Location: Decision Framework

Choosing the right materials for your specific BC location ensures optimal performance and value.

Coastal Waterfront Properties (0-200m from saltwater)

Municipalities: White Rock beachfront, North Vancouver waterfront, Tsawwassen beach areas

Recommended Materials:

Hardware: 316 stainless steel minimum, 2205 duplex stainless recommended

Glass: Laminated (wind resistance and post-break safety)

Finish: Electropolished or brushed stainless (minimizes chloride accumulation)

Expected Lifespan: 30-40+ years with 2205 duplex (Viewrail, 2024), 25-30 years with 316 stainless

Maintenance: Monthly freshwater rinsing

Cost Impact: Premium (highest material costs but necessary for longevity)

Near-Coastal Properties (200-600m from saltwater)

Municipalities: White Rock residential, North Shore coastal neighborhoods, Richmond waterfront, Delta coastal, portions of Vancouver

Recommended Materials:

Hardware: 316 stainless steel OR quality powder-coated aluminum (AAMA 2605)

Glass: Laminated recommended for exposed exterior

Finish: AAMA 2605 powder coating provides 10-year warranty (RailFX, 2024)

Expected Lifespan: 20-30 years depending on material choice

Maintenance: Quarterly freshwater rinsing

Cost Impact: Standard-Premium (powder-coated aluminum more economical, 316 stainless more durable)

Moderate Coastal (600m-2km from saltwater)

Municipalities: Most of Vancouver, Burnaby, New Westminster, Coquitlam, inland Richmond/Delta

Recommended Materials:

Hardware: AAMA 2605 powder-coated aluminum (excellent value) OR 304/316 stainless

Glass: Tempered suitable for most applications, laminated for frameless systems

Finish: Standard powder coating performs well

Expected Lifespan: 25-30+ years for quality powder coating

Maintenance: Semi-annual cleaning

Cost Impact: Standard pricing

Inland Fraser Valley Properties (2km+ from saltwater)

Municipalities: Surrey (majority), Langley, Abbotsford, Chilliwack, Maple Ridge, Mission, Pitt Meadows

Recommended Materials:

Hardware: Any quality system (304 stainless acceptable, powder aluminum excellent)

Glass: Tempered for most applications, laminated for frameless

Finish: Standard options all perform well

Expected Lifespan: 30+ years for powder-coated aluminum in inland climates (Hugh Aluminum, 2024)

Maintenance: Annual inspection and cleaning

Cost Impact: Standard to value (most cost-effective installations)

Material Performance Comparison Table

Distance from Water | Municipality Examples | Hardware Specification | Expected Lifespan | Maintenance |

|---|---|---|---|---|

0-200m (Extreme) | White Rock beachfront, North Van waterfront | 316 SS minimum, 2205 duplex best | 30-40+ years | Monthly rinse |

200-600m (High) | White Rock, North/West Van coastal, Richmond waterfront | 316 SS or AAMA 2605 | 20-30 years | Quarterly rinse |

600m-2km (Moderate) | Vancouver, Burnaby, Coquitlam | AAMA 2605 or 304/316 SS | 25-30+ years | Semi-annual clean |

2km+ (Inland) | Fraser Valley (all) | Any quality system | 30+ years | Annual clean |

For detailed material specifications across all applications, see our guide on corrosion-resistant coastal glass railings.

BC Building Code Compliance Across Municipalities

All BC municipalities follow provincial building code with minor local variations.

Provincial BC Building Code Requirements (Universal)

The following requirements apply across all Metro Vancouver and Fraser Valley municipalities:

When guards are required: Guards must be installed where there is a drop of more than 600mm (24 inches) (Glass Railing Store, 2024).

Height requirements by elevation:

Decks up to 1.8m (5 feet 10 inches) above grade: 900mm (36 inches) minimum (Tenmar, 2024)

Decks and balconies above 1.8m: 1,070mm (42 inches) minimum (Tenmar, 2024)

Commercial applications: 1,070mm (42 inches) regardless of elevation

Opening size restrictions: No opening in the guard may allow passage of a spherical object having a diameter of 100mm (approximately 4 inches) (Glass Railing Store, 2024).

Glass thickness requirements: All glass panel railings must be at least 12mm (0.5 inches) thick for laminated or tempered safety glass meeting CAN/CGSB-12.1-M90 standards (Glass Railing Store, 2024).

Load requirements: Guards must withstand 200 lb concentrated load minimum plus 50 plf uniform horizontal load (Greco Railings, 2024).

2024 BC Building Code updates: The 2024 edition introduced updates for guard load resistance and glass design standards, reflecting seismic and wind-zone improvements (Tenmar, 2024).

For complete code requirements, see our BC Building Code guide for glass railings.

Municipal Code Variations

While provincial code provides the baseline, individual municipalities may enforce additional requirements:

Vancouver: May have design review requirements for heritage districts and certain neighborhoods. High-rise developments face additional wind load calculations.

North Shore (North Van, West Van): Exposed waterfront and hillside properties require enhanced wind and seismic engineering.

Surrey, Langley, Abbotsford: Generally follow provincial code without significant additional requirements.

Richmond, Delta: Waterfront properties may need enhanced wind load calculations.

Always verify specific requirements with your local building department before finalizing designs.

Permit Processes by Municipality

Typical Timelines:

Vancouver: 4-8 weeks

North Shore municipalities: 4-8 weeks

Burnaby, New Westminster, Richmond: 3-6 weeks

Surrey, Coquitlam, Port Coquitlam: 3-6 weeks

Fraser Valley (Langley, Abbotsford, Chilliwack, Maple Ridge, Mission): 2-4 weeks

Required Documents (all municipalities):

Site plan showing proposed railing locations

Structural details and specifications

Engineer-sealed drawings for frameless systems

Load calculations

Material specifications

Engineer Requirements for Frameless Systems

Frameless or "topless" glass railing systems must include engineer-sealed shop drawings in BC verifying load capacity and glass specifications (Tenmar, 2024). This requirement applies uniformly across all municipalities from Vancouver to Chilliwack.

Professional engineers must verify that systems meet structural requirements before permits are issued. Semi-frameless systems with top rails and posts generally don't require engineering certification for standard residential applications, though complex installations may still warrant professional engineering.

Inspection Timelines

Most municipalities require two inspections:

Rough-in inspection: Before final installation, verify mounting points and structural adequacy

Final inspection: After installation completion, verify code compliance

Schedule inspections 3-5 business days in advance in most municipalities. Vancouver and North Shore may require 5-7 days notice during busy construction seasons.

Installation Costs Across Metro Vancouver & Fraser Valley

Understanding regional cost variations helps budget appropriately for your location.

Vancouver & North Shore Pricing (Premium Tier)

Vancouver and North Shore installations typically cost 15-25% more than Fraser Valley projects due to several factors:

Labor Cost Premium: Metro Vancouver labor rates run significantly higher than Fraser Valley due to cost of living, demand, and unionized construction sectors in urban areas.

Urban Access Challenges: Downtown and high-rise projects face parking permit costs, material hoisting fees, restricted work hours, and elevator access scheduling. These add $500-$1,500 to typical projects.

Permit Fee Variations: Building permit fees typically range from $200-$800 depending on project scope and municipality (Glass Railing Store, 2024), with Vancouver trending toward higher fees ($500-$800) versus Fraser Valley municipalities ($200-$400).

Stricter Requirements: Vancouver's heritage districts and design review processes may add architectural consultation costs. North Shore wind load engineering adds $800-$1,500 for waterfront or exposed hillside properties.

Material Transport: While material costs remain similar across regions, downtown Vancouver delivery and handling logistics add minor premiums.

Fraser Valley Pricing (Standard Tier)

Fraser Valley installations (Langley, Abbotsford, Chilliwack, eastern communities) offer cost advantages:

Lower Labor Rates: Skilled trades in Fraser Valley charge 15-25% less than Vancouver counterparts while delivering equivalent quality.

Simpler Logistics: Ground-level access, easier parking, and residential neighborhood work conditions reduce installation time and complications.

Faster Permits: The 2-4 week permit timeline versus Vancouver's 4-8 weeks reduces project carrying costs and allows faster completion.

Competitive Market: Multiple installers serving Fraser Valley create competitive pricing pressure benefiting homeowners.

Cost Factors Affecting Regional Pricing

System Type:

Frameless: Premium pricing all regions (laminated glass requirement increases costs 50-100%) (San Diego Cable Railings, 2024)

Semi-frameless: Standard pricing, most cost-effective option

Custom/curved: Premium pricing for specialty fabrication

Linear Footage: Longer runs reduce per-foot costs. A 40-linear-foot deck costs less per foot than a 15-foot balcony installation.

Height Requirements: Commercial-height guards (42 inches) require more material than residential (36 inches), increasing costs proportionally.

Material Selection:

2205 duplex stainless: Premium pricing (White Rock beachfront)

316 stainless steel: Mid-premium pricing (North Shore coastal)

AAMA 2605 powder aluminum: Standard pricing (most locations)

304 stainless: Value pricing (Fraser Valley inland)

Access Complexity:

Ground level, open access: Standard pricing

Second/third floor: Slight premium

High-rise: Significant premium (Vancouver)

Difficult terrain: Premium (North Shore hillsides)

Seasonal Pricing Variations

Summer (May-September): Peak demand creates 10-15% pricing premiums in Vancouver and North Shore. Fraser Valley sees smaller premiums (5-10%) due to more available contractors.

Spring/Fall (April, October): Shoulder seasons offer standard pricing with good installer availability. Weather remains generally cooperative for installation.

Winter (November-March): Some installers offer 5-10% discounts for winter bookings due to lower demand. Weather delays are more common but proper scheduling accounts for this. Fraser Valley has better winter weather windows than Vancouver.

Hidden Costs by Municipality

Vancouver Specific:

Parking permits: $50-$200

Material delivery surcharges: $100-$300

Elevator booking fees (condos): $100-$500

Noise bylaw compliance (restricted hours): Potential labor premium

North Shore Specific:

Specialized access equipment (hillsides): $500-$2,000

Enhanced engineering: $800-$1,500

Premium material delivery: $200-$500

Fraser Valley:

Extended travel time for Vancouver-based installers: $200-$400

Generally fewer hidden costs than urban areas

Sample Cost Comparison

Project: 30 linear feet of semi-frameless glass railing, residential deck, powder-coated aluminum with tempered glass

Location | Material Cost | Labor | Permit | Total | Notes |

|---|---|---|---|---|---|

Vancouver | $3,500 | $2,800 | $600 | $6,900 | +Premium labor, urban access |

North Shore | $3,700 | $3,000 | $650 | $7,350 | +Marine materials, hillside access |

Burnaby/Richmond | $3,500 | $2,500 | $500 | $6,500 | Standard Metro Van pricing |

Surrey/Langley | $3,500 | $2,200 | $350 | $6,050 | -Lower labor, faster permits |

Abbotsford/Chilliwack | $3,500 | $2,000 | $300 | $5,800 | -Lower labor, simpler logistics |

Seasonal Installation Timing in BC

BC's wet climate creates distinct installation seasons and weather considerations.

Optimal Installation Windows (May-September)

The dry season from May through September provides ideal conditions for glass railing installations across all BC locations. Advantages include:

Consistent Weather: Minimal rainfall allows proper sealant curing without weather interruptions. Most sealants require 24-48 hours dry weather for optimal curing.

Extended Daylight: Longer summer days enable more productive work hours and flexibility in scheduling.

Better Access: Dry ground conditions facilitate equipment access and material handling, particularly important for North Shore hillside properties and rural Fraser Valley locations.

Faster Timelines: Absence of weather delays means projects complete on original schedules. What might take 3-5 days in summer could require 5-8 days in winter due to weather interruptions.

Rainy Season Considerations (October-April)

BC's rainy season doesn't prohibit glass railing installation but requires additional planning:

Weather Monitoring: Installers must track weather forecasts closely and adjust schedules around rain events. This adds flexibility requirements to project timelines.

Protective Measures: Temporary covers protect mounting areas during sealant curing. Quality installers employ weather-resistant sealants rated for damp conditions.

Extended Timelines: Add 1-2 weeks to project timelines for weather buffer. A project completing in 1 week during summer might require 2-3 weeks in winter.

Regional Variations: Fraser Valley municipalities receive 25-30% less rainfall than Vancouver, making winter installations more predictable in Abbotsford and Langley than Vancouver or North Shore.

Weather-Related Project Delays

Vancouver & North Shore: Highest rainfall (1,100-1,200mm annually) creates most weather sensitivity. October through March sees frequent rain requiring flexible scheduling.

Fraser Valley: Lower rainfall (800-900mm annually) provides better winter installation windows. Abbotsford and Chilliwack often have dry periods even in winter months.

Temperature Considerations: Fraser Valley experiences colder winter temperatures than coastal areas. Sealants must be rated for temperature ranges down to -20°C. Summer heat (occasionally reaching 35°C) also requires appropriate sealant specifications.

Curing Times in BC's Wet Climate

Sealant Curing: Most sealants require 24-48 hours dry weather for initial cure, 72 hours for full cure. BC's climate means installers must time work carefully around weather windows.

Concrete/Mounting Substrate: New concrete should cure minimum 28 days before glass railing installation. BC's moisture can slow curing; professional installers verify substrate readiness before mounting.

Year-Round Installation: Despite weather challenges, professional installers work year-round in BC using weather-resistant materials and protective measures. Projects scheduled for November through March should expect potential weather delays and flexible timelines.

Choosing a Glass Railing Installer in Your Area

Selecting the right installation company ensures code compliance, proper material selection, and long-term performance.

What to Look for in Local Installers

BC Licensing and Insurance: Verify contractor holds valid BC business license and appropriate liability insurance ($2 million minimum). Workers' compensation coverage protects you from liability for on-site injuries.

Local Experience: Installers familiar with your municipality understand local permit processes, building department expectations, and code interpretations. Ask for examples of projects in your specific city or neighborhood.

Material Knowledge: Quality installers should explain differences between 304 and 316 stainless steel, understand coastal exposure zones, and recommend appropriate systems for your location. If they can't explain why 316 stainless matters for White Rock waterfront versus Abbotsford inland, find another installer.

Portfolio Review: Request photos of completed projects in similar locations. North Shore waterfront installations differ from Fraser Valley residential projects. See examples matching your property type and exposure.

Engineering Relationships: For frameless systems, installers should have relationships with structural engineers providing sealed drawings. This indicates they regularly handle complex installations.

Questions to Ask Potential Contractors

Location-Specific Questions:

"How many installations have you completed in [your municipality]?"

"What material do you recommend for my distance from saltwater?" (Test their coastal zone knowledge)

"How familiar are you with [Vancouver/Surrey/Abbotsford] building department requirements?"

"What's your typical permit timeline in my municipality?"

Technical Questions:

"Why do you recommend [material X] for my location?"

"What grade of stainless steel are you specifying and why?"

"Is the glass tempered or laminated, and why that choice?"

"Will my system require engineer-sealed drawings?"

Process Questions:

"Do you handle all permit applications or do I need to?"

"What's included in your quote?" (Permits, engineering, disposal, cleanup)

"What's your payment schedule?"

"Do you warranty your installation? For how long?"

Timeline Questions:

"What's your current lead time from contract to start?"

"How long will installation take?"

"What could delay the project?" (Weather, permits, material lead times)

"Do you work year-round or only dry season?"

Verifying Credentials and Experience

Check References: Ask for 3-5 references from recent projects in your area. Call them. Ask about communication, quality, timeline adherence, and problem resolution.

Online Reviews: Check Google, HomeStars, and industry-specific review platforms. Look for patterns in feedback rather than single reviews.

Better Business Bureau: Verify BBB rating and check for unresolved complaints.

WorkSafeBC: Verify contractor maintains WorkSafeBC coverage. This protects you from liability if workers are injured on your property.

Licensing: Verify business license through your municipality. Some municipalities require specific trades licensing for structural work.

Portfolio Review Considerations

Look for:

Projects similar to yours (coastal vs inland, residential vs commercial)

Quality of installations (clean lines, proper spacing, professional finish)

Variety of systems (frameless, semi-frameless, different mounting methods)

Completed projects, not just renders or plans

Ask to visit: Request addresses of nearby completed projects you can drive by. Seeing finished installations in person reveals quality better than photos.

Recent work: Focus on projects completed within past 2 years. Industry standards and materials evolve; recent work demonstrates current best practices.

Timeline Expectations by Region

Vancouver/North Shore:

Contract to permit approval: 4-8 weeks

Permit to material ordering: 1-2 weeks

Material fabrication: 3-6 weeks

Installation: 2-5 days typical residential

Total timeline: 10-16 weeks from contract to completion

Fraser Valley:

Contract to permit approval: 2-4 weeks

Permit to material ordering: 1 week

Material fabrication: 3-6 weeks

Installation: 2-5 days typical residential

Total timeline: 7-12 weeks from contract to completion

Add buffers for:

Complex custom systems: +2-4 weeks fabrication

Winter weather delays: +1-3 weeks

High-rise logistics: +1-2 weeks coordination

Professional glass railing installation services communicate timelines clearly and update you on any changes.

Frequently Asked Questions

What are the best glass railings for Vancouver coastal properties?

For Vancouver coastal properties within 600 meters of saltwater, specify 316 stainless steel hardware minimum (contains 2-3% molybdenum for saltwater resistance) (Dahlstrom Rollform, 2024) or quality powder-coated aluminum with AAMA 2605 finish (RailFX, 2024). Use laminated glass for exterior applications to provide wind resistance and post-break safety (Viewrail, 2024). Properties within 200 meters of shore (White Rock beachfront, North Vancouver waterfront) should use 2205 duplex stainless steel for maximum corrosion resistance with PREN score of 34 (Viewrail, 2024).

How much more expensive are glass railings in Vancouver vs Fraser Valley?

Vancouver glass railing installations typically cost 15-25% more than Fraser Valley projects due to higher labor costs, urban access challenges, stricter permitting, and longer timelines. A project costing $6,000-$7,000 in Abbotsford or Langley might run $7,000-$8,500 in Vancouver or North Shore for identical specifications. Material costs remain similar across regions as glass and hardware source from central suppliers. The labor premium accounts for most cost difference. Permit fees also trend higher in Vancouver ($500-$800) versus Fraser Valley municipalities ($200-$400) (Glass Railing Store, 2024).

Do I need different materials for White Rock waterfront vs Abbotsford?

Yes. White Rock waterfront properties within 200 meters of the ocean fall in the extreme coastal exposure zone where highest corrosion rates occur (International Molybdenum Association, 2024). These locations require 316 stainless steel minimum or 2205 duplex stainless recommended (Viewrail, 2024). Abbotsford properties sit 70+ kilometers inland with no saltwater exposure, allowing cost-effective materials like powder-coated aluminum or 304 stainless steel to perform excellently. Powder-coated aluminum lasts 30+ years in inland environments (Hugh Aluminum, 2024) versus 20-25 years in coastal zones.

What are the permit requirements for glass railings in Vancouver?

Vancouver glass railing installations require building permits for most applications. Guards must be installed where drop exceeds 600mm (24 inches) (Glass Railing Store, 2024). Frameless systems must include engineer-sealed shop drawings verifying load capacity and glass specifications per CAN/CGSB standards (Tenmar, 2024). Vancouver permit timelines typically run 4-8 weeks for plan review and approval. Permit fees range $500-$800 depending on project scope. Required documents include site plan, structural details, material specifications, and load calculations. Some heritage districts have additional design review requirements.

How long does glass railing installation take in Metro Vancouver?

Timeline depends on location and project complexity. Vancouver and North Shore projects typically require 10-16 weeks total from contract to completion: 4-8 weeks permit approval, 1-2 weeks material ordering, 3-6 weeks fabrication, 2-5 days installation. Fraser Valley timelines run faster at 7-12 weeks total: 2-4 weeks permits, 1 week ordering, 3-6 weeks fabrication, 2-5 days installation. Add 2-4 weeks for complex custom systems and 1-3 weeks buffer for winter weather delays. High-rise Vancouver installations add 1-2 weeks for logistics coordination. Professional installers provide detailed timelines during consultation.

When is the best time to install glass railings in BC?

May through September provides optimal installation conditions across all BC locations with minimal rainfall, warm temperatures for sealant curing, and extended daylight hours. October through April rainy season allows installation but requires weather monitoring and flexible scheduling. Add 1-2 weeks to project timelines for weather buffer during rainy season. Fraser Valley municipalities (Abbotsford, Langley, Chilliwack) receive 25-30% less rainfall than Vancouver, providing better winter installation windows. Most professional installers work year-round using weather-resistant materials and protective measures. Summer demand creates 10-15% pricing premiums; winter may offer 5-10% discounts despite weather challenges.

What's the difference between North Vancouver and Surrey for glass railings?

North Vancouver properties face coastal exposure (many within 100-600m of Burrard Inlet and Howe Sound) requiring marine-grade materials like 316 stainless steel or AAMA 2605 powder coating (Dahlstrom Rollform, 2024). Hillside locations require enhanced wind load engineering. Permits take 4-8 weeks. Costs run premium due to specialized materials and access challenges. Surrey properties sit mostly inland (2km+ from saltwater) allowing standard materials like powder-coated aluminum or 304 stainless steel to perform well. Permits process in 3-6 weeks. Costs run standard Metro Vancouver rates, lower than North Shore premium. Both follow same BC Building Code for heights, loads, and glass specifications.

Do I need laminated glass for my Vancouver condo balcony?

Most Vancouver condo balconies require laminated glass due to commercial building code requirements for multi-family properties (Glass Railing Store, 2024). Frameless glass railing systems without top rails require laminated glass by IBC 2021 (Greco Railings, 2024). Semi-frameless systems with posts and top rails may allow tempered glass depending on strata regulations and building codes. Laminated glass costs 50-100% more than tempered (San Diego Cable Railings, 2024) but provides post-break safety important for high-rise applications. Verify requirements with your strata council and building department before finalizing specifications.

How do I choose between 316 stainless and powder-coated aluminum?

Decision depends on your distance from saltwater. Properties within 0-200m extreme coastal zone (White Rock beachfront, North Van waterfront) should use 316 stainless steel minimum for its 2-3% molybdenum content providing superior saltwater resistance (Dahlstrom Rollform, 2024). Properties 200-600m from water (most of White Rock, North Shore coastal neighborhoods, Richmond waterfront) perform well with either 316 stainless or quality AAMA 2605 powder-coated aluminum (RailFX, 2024). Powder aluminum costs less and provides 20-25 year lifespan in coastal zones. Properties 600m+ from saltwater (Vancouver city, Burnaby, all Fraser Valley) excel with powder-coated aluminum lasting 30+ years (Hugh Aluminum, 2024).

What glass railing maintenance is required in coastal BC?

Maintenance schedules vary by coastal exposure. Properties within 200m of saltwater (White Rock, North Van waterfront) require monthly freshwater rinsing to remove salt deposits before corrosion begins. Properties 200-600m from water need quarterly cleaning. Properties 600m-2km from saltwater benefit from semi-annual cleaning. Inland Fraser Valley properties require only annual inspection and cleaning. Use mild soap and water; avoid abrasive cleaners or chlorine-based products damaging stainless steel. Even marine-grade materials benefit from regular maintenance. Quality powder-coated aluminum with AAMA 2605 finish resists corrosion but freshwater rinsing extends lifespan. With proper care, expect 20-40+ years depending on material and location (Viewrail, 2024).

Summary: Choosing the Right Glass Railing System for Your BC Location

Your property's location in Metro Vancouver or Fraser Valley determines material requirements, costs, permit timelines, and installation considerations for glass railing systems. Coastal properties within 600 meters of saltwater require marine-grade materials like 316 stainless steel or AAMA 2605 powder-coated aluminum. Inland Fraser Valley properties enjoy material flexibility and cost advantages while achieving 30+ year lifespans with standard specifications.

Key location-based takeaways:

Coastal exposure matters: Distance from saltwater (0-200m extreme, 200-600m high, 600m+ moderate, 2km+ inland) determines material requirements and lifespan expectations

Regional cost variations: Vancouver and North Shore installations run 15-25% higher than Fraser Valley due to labor premiums, urban logistics, and stricter permitting

Municipal permit timelines: Vancouver requires 4-8 weeks, Fraser Valley municipalities process in 2-4 weeks, affecting total project timelines

BC Building Code compliance: Universal requirements (heights, loads, glass thickness) apply across all municipalities with minor local variations for heritage districts and exposed properties

Seasonal timing: May-September provides optimal conditions; October-April requires weather monitoring and flexible scheduling, with Fraser Valley offering better winter windows than coastal areas

Material selection framework: Match hardware specifications to your coastal zone for optimal performance and value—marine-grade for waterfront, standard for inland

Professional installation ensures code compliance, proper material selection for your specific coastal exposure, and long-term performance. Whether planning a Vancouver waterfront project, North Shore mountain-view deck, or Fraser Valley custom home, location-specific expertise delivers best results.

Ready to explore glass railing solutions for your Metro Vancouver or Fraser Valley property? Contact Tenmar for a location-specific consultation and site assessment. Our team specializes in BC Building Code-compliant installations across all municipalities, with expertise in coastal material selection and regional requirements.

Schedule a consultation | Browse our locations | View our application portfolio | Explore property types we serve